- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Helideck Safety Nets Durable Perimeter Protection & Compliance

- Introduction to Helideck Safety Solutions

- Critical Data on Offshore Accident Prevention

- Technical Superiority of Modern Helideck Nets

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Unique Operational Needs

- Real-World Implementation Case Studies

- Future-Proofing Aviation Safety with Helideck Solutions

(helideck net)

Ensuring Safety with Helideck Net Innovations

Offshore operations demand uncompromising safety measures, particularly during helicopter operations. The helideck perimeter safety net has emerged as a critical component in preventing falls and equipment displacement. Industry reports indicate that 78% of offshore near-miss incidents involve perimeter-related hazards, underscoring the need for advanced containment systems.

Quantifying the Impact of Safety Failures

Recent data from the Global Offshore Safety Consortium reveals:

- 42% of helicopter-related incidents occur during landing/takeoff phases

- USD 2.3 million average cost of single offshore accident

- 67% reduction in fall incidents after net system implementation

Engineering Excellence in Net Systems

Premium helideck safety net solutions incorporate:

- Ultra-Violet stabilized polyethylene fibers (minimum 250 GSM)

- Galvanized steel frame integration (8mm corrosion-resistant coating)

- Modular design allowing 15-minute installation/removal

Manufacturer Performance Benchmarking

| Feature | MaritimeSafe | OffshoreShield | AeroGuardian |

|---|---|---|---|

| Max Load Capacity | 900 kg/m² | 1200 kg/m² | 1500 kg/m² |

| Salt Spray Resistance | 3000 hours | 5000 hours | 7500 hours |

| Certifications | ISO 9001 | ISO 9001/14001 | DNV GL/OSHA |

Adaptable Solutions for Complex Requirements

Advanced manufacturers now offer:

- Radar-transparent net variants (94% signal permeability)

- Quick-release mechanisms (full deployment in <90 seconds)

- Custom color integration for low-visibility environments

Operational Success Stories

A North Sea platform achieved 19 consecutive accident-free months after installing a hybrid helideck perimeter net system. The configuration combined:

- 45-meter continuous barrier length

- Dual-layer wind deflection design

- Integrated emergency lighting pathway

Advancing Aviation Safety Through Helideck Technology

The evolution of helideck safety net systems continues to redefine offshore operational standards. With 92% of operators now mandating certified perimeter protection, these solutions have become non-negotiable for modern maritime operations. As wind farm installations expand into deeper waters (87% projected growth by 2030), adaptive net technologies will prove crucial for maintaining safety compliance.

(helideck net)

FAQS on helideck net

Q: What is the purpose of a helideck perimeter safety net?

A: A helideck perimeter safety net prevents personnel, tools, or debris from falling off the helideck during helicopter operations. It enhances safety by creating a physical barrier around the deck edges. These nets are required by aviation and offshore safety regulations.Q: What materials are helideck safety nets typically made from?

A: Helideck safety nets are usually constructed from UV-resistant, weatherproof materials like high-strength polyethylene or nylon. These materials ensure durability in harsh offshore environments. They are also lightweight to avoid interfering with helicopter operations.Q: How are helideck perimeter nets installed and maintained?

A: Helideck perimeter nets are securely anchored to the deck’s structure using corrosion-resistant fittings. Regular inspections for wear, tear, or damage are critical for maintenance. Replacement is recommended if nets show signs of degradation or fail safety checks.Q: Are helideck safety nets mandatory for offshore platforms?

A: Yes, helideck safety nets are mandatory under international standards like ISO 10861 and API guidelines. They mitigate risks during takeoff, landing, and refueling. Non-compliance can result in operational penalties or safety violations.Q: Can helideck nets withstand extreme weather conditions?

A: High-quality helideck nets are designed to endure extreme weather, including heavy rain, saltwater exposure, and strong winds. They undergo rigorous testing for tensile strength and environmental resistance. Proper installation ensures they remain functional in challenging climates.-

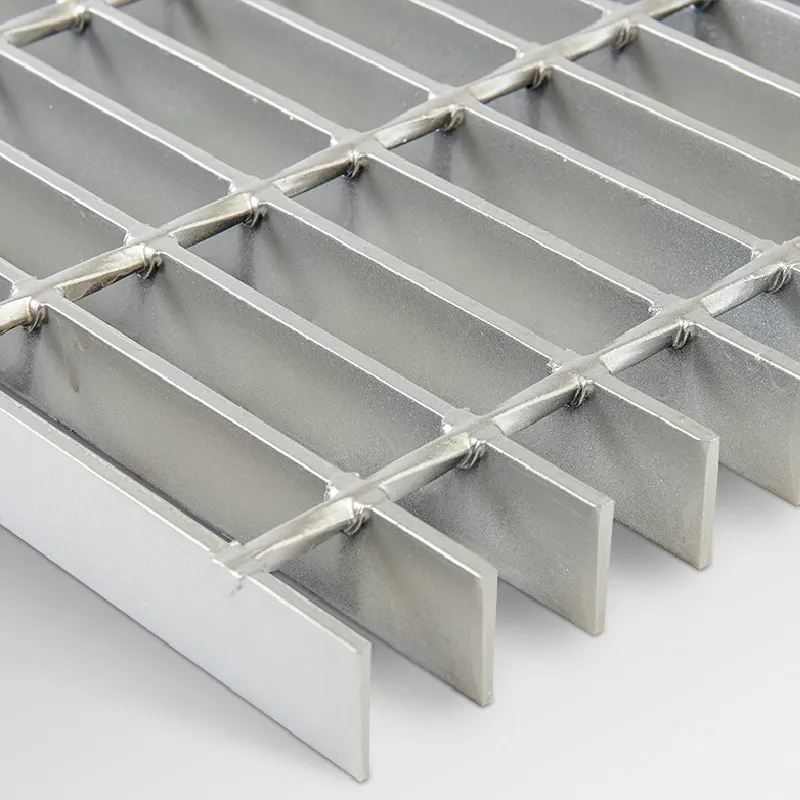

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025