- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

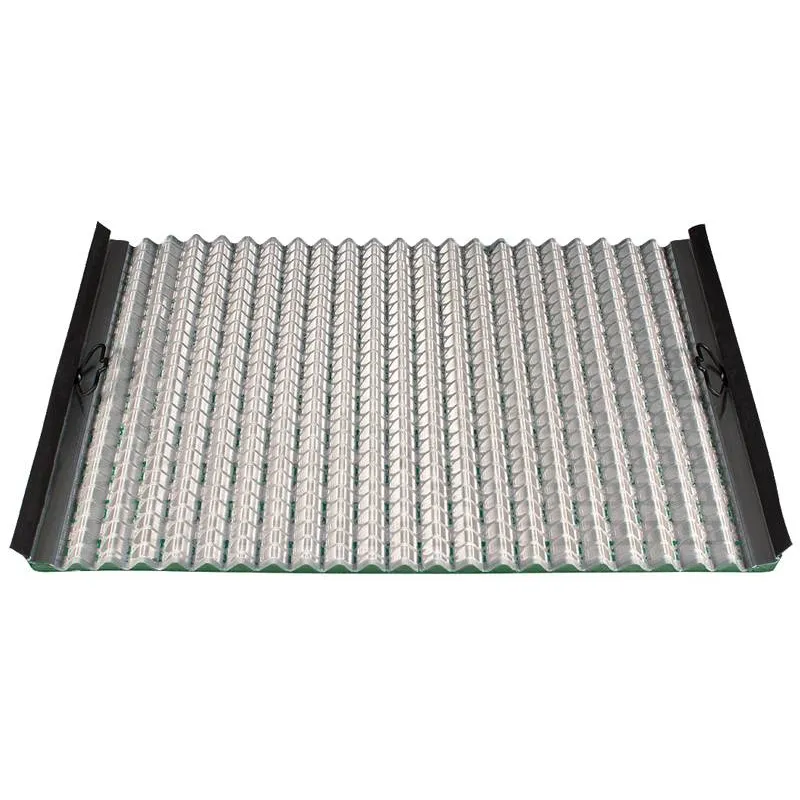

concrete weight coating mesh

Concrete weight coating mesh plays a pivotal role in the construction and maintenance of undersea pipelines, providing essential weight and protection against environmental factors. Born from advanced engineering and years of field expertise, this innovative solution stands out in the realm of subsea applications, combining both structural integrity and practicality.

Let’s delve into a real-life experience that highlights the application of concrete weight coating mesh. In the North Sea, a renowned engineering company was tasked with installing a series of undersea pipelines. Faced with unpredictable weather conditions and potential underwater currents, the team needed a robust solution to safeguard the pipelines. The choice was clear utilizing concrete weight coating mesh not only provided the requisite stability but also simplified the transportation and installation process due to its adaptable nature.

From an expert perspective, understanding the structure and functionality of the concrete weight coating mesh is crucial. The mesh itself is designed to enhance the adhesion of concrete to the pipeline, ensuring that the coating remains intact over time. It is typically crafted from high-quality, corrosion-resistant materials, allowing it to withstand harsh marine environments. The mesh's grid pattern is engineered to evenly distribute weight, maintaining the pipeline’s position on the sea floor and reducing the risk of displacement caused by ocean currents or tectonic activity.

In terms of authoritativeness, various studies and field tests underscore the reliability of concrete weight coating mesh. Research conducted by leading maritime institutes has shown a significant reduction in pipeline damage and displacement in installations utilizing this technology. This authoritative backing has propelled concrete weight coating mesh to the forefront as a trusted solution in the oil and gas industry.

concrete weight coating mesh

Moreover, manufacturers adhere to stringent quality control processes, which further amplify the trustworthiness of this product. The standardization in production ensures each mesh unit meets international safety and performance criteria, providing peace of mind to engineers and project managers tasked with high-stakes pipeline installations.

Looking at the product’s commercial aspect, suppliers offer bespoke solutions, tailoring concrete weight coating mesh specifications to meet the unique demands of each project. This customization aspect not only showcases the mesh’s versatility but also underlines its suitability for a wide range of environmental conditions and project scales.

For prospective buyers considering concrete weight coating mesh, it's imperative to assess suppliers based on their track record, client testimonials, and adherence to technical specifications. Engaging with a supplier who can demonstrate a portfolio of successful projects and provide comprehensive technical support can enhance project outcomes significantly.

In conclusion, concrete weight coating mesh emerges as a front-runner in subsea pipeline projects, merging experiential insights with empirical evidence. Its proven track record, coupled with expert validation and rigorous quality standards, ensures it remains a benchmark for reliability and efficiency in maritime engineering solutions.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025