- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

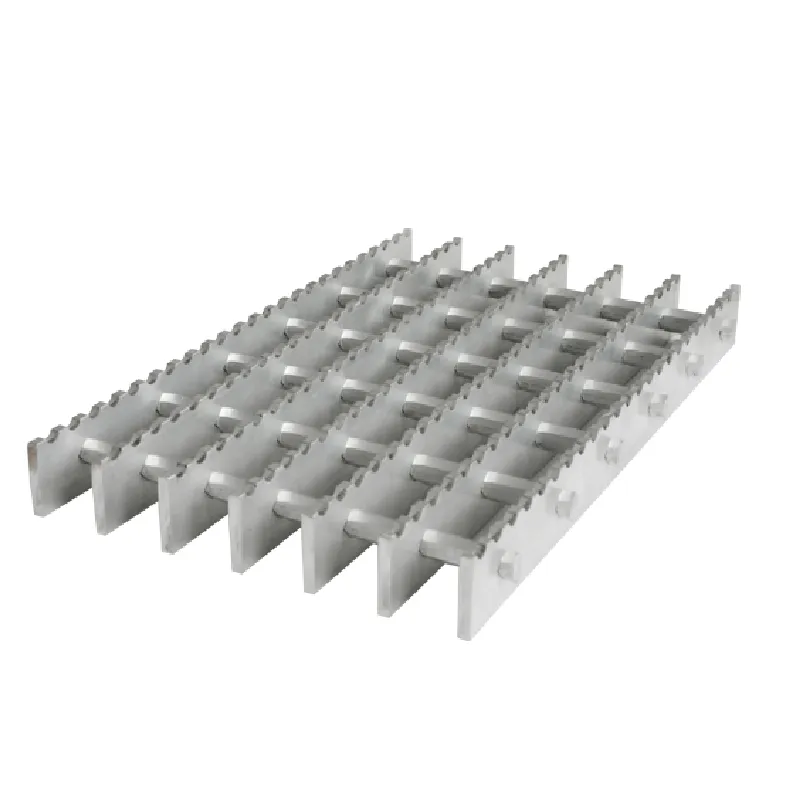

serrated metal grating

Understanding Serrated Metal Grating A Versatile Solution for Various Applications

Serrated metal grating has emerged as a pivotal solution in various industries, offering both functionality and safety. This specialized type of grating is characterized by its unique serrated edge design, which significantly enhances its performance, especially in environments where slip resistance is crucial. In this article, we will delve into the unique features, benefits, applications, and manufacturing processes of serrated metal grating, demonstrating how it has become an indispensable component across multiple sectors.

What is Serrated Metal Grating?

Serrated metal grating is a type of flooring or covering made from metal bars that are arranged in a grid pattern. The distinguishing feature of this grating is its serrated surface, which means that the top edge of the bars has been notched or angled in a way that creates friction. This design is intentional, aimed at improving slip resistance. Serrated grating is typically made from durable materials such as steel, stainless steel, or aluminum, making it suitable for a range of harsh environments and heavy loads.

Advantages of Serrated Metal Grating

One of the most significant advantages of serrated metal grating is its unparalleled slip resistance. The serrations in the grating provide additional traction, making it an ideal choice for areas that may be exposed to water, oil, or other slippery substances. This feature is particularly beneficial in industrial settings where safety is a top priority.

Moreover, serrated metal grating is known for its excellent load-bearing capabilities

. The construction of the grating allows it to support heavy equipment and foot traffic without bending or breaking. This makes it suitable for use in locations like warehouses, factories, and commercial establishments where heavy loads are commonplace.Another advantage is its durability. Serrated metal grating is resistant to corrosion, rust, and other forms of degradation, giving it a long lifespan even in challenging environmental conditions. This contributes to lower replacement costs and less maintenance, ultimately benefiting the bottom line for businesses.

Applications of Serrated Metal Grating

serrated metal grating

Serrated metal grating is utilized in a multitude of applications across various industries. In industrial settings, it is commonly used for flooring, walkways, platforms, and stair treads. The increased safety due to the slip-resistant surface makes it ideal for areas where workers may encounter wet or oily surfaces.

In the realm of construction, serrated metal grating can be seen in bridges and catwalks, where structural integrity and safety are paramount. The transportation industry also benefits from this grating, as it provides secure footing on loading docks and rail platforms.

Additionally, serrated metal grating is increasingly used in architectural applications. Its aesthetic appeal, combined with its functional reliability, makes it a popular choice for modern building designs. Outdoor spaces such as parks and recreational areas have also incorporated this type of grating, using it in benches, railings, and other features that enhance both safety and design.

Manufacturing Processes

The manufacturing of serrated metal grating involves several key processes. Initially, raw metal materials are cut into specific sizes and shapes. The bars are then arranged in a grid pattern and welded together to create a solid structure. The serration process is a critical step, where the edges of the bars are notched or stamped, creating the distinctive traction surface.

Quality control is essential throughout the manufacturing process to ensure that the grating meets specific safety and performance standards. This includes testing for load capacity, corrosion resistance, and slip resistance to ensure that the final product is both reliable and effective.

Conclusion

Serrated metal grating has proven itself as a versatile and essential material in various applications. Its unique features, such as enhanced slip resistance and durability, make it a preferred choice across numerous industries. Whether in industrial facilities, construction sites, or architectural designs, serrated metal grating continues to provide safety, strength, and aesthetic appeal. As industries evolve and safety standards become increasingly stringent, the importance of materials like serrated metal grating will only continue to grow, shaping the future of construction and design.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025