- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Benefits and Applications of Concrete Weight Coating in Pipeline Protection

Understanding Concrete Weight Coating Applications and Benefits

Concrete weight coating (CWC) is a specialized process widely used in various industries to provide weight and protection to pipelines, especially in offshore applications. This coating technique enhances the stability and integrity of pipelines that are often exposed to challenging environmental conditions. In this article, we will explore the concept of concrete weight coating, its applications, benefits, and the manufacturing process involved.

What is Concrete Weight Coating?

Concrete weight coating involves applying a layer of concrete to the external surface of a pipeline. The primary purpose of this coating is to provide additional weight to the pipe, which helps to keep it anchored on the seabed. This is particularly crucial for pipes transporting oil, gas, and other fluids, as it minimizes the risk of buoyancy that could cause the pipeline to be displaced or damaged.

The coating not only adds weight but also serves as a protective barrier against external forces, such as marine organisms, corrosion, and impacts from dropped objects. The thickness and density of the coating can vary based on specific project requirements, ensuring that the pipeline remains stable and secure in different environmental conditions.

Applications of Concrete Weight Coating

Concrete weight coating is predominantly used in the oil and gas sector, especially for subsea pipelines. However, its applications extend to other industries as well, including

1. Offshore Pipelines The most significant application of CWC is in offshore pipelines delivering hydrocarbons from underwater sources to onshore facilities. It provides the necessary ballast to prevent displacement due to currents and waves.

2. Wind Farm Foundations CWC is utilized in the construction of monopile foundations for offshore wind turbines. The added weight helps to stabilize the structures against strong marine currents and storms.

3. Marine Structures Other marine structures, such as subsea installations, platforms, and anchors, often employ concrete weight coating to ensure stability and resilience against harsh marine environments.

4. Underwater Cables CWC can be used on underwater cables to protect them from damage and to minimize the risk of them floating away due to water movement.

Benefits of Concrete Weight Coating

The advantages of using concrete weight coating are numerous

concrete weight coating

- Increased Stability The additional weight provided by the concrete coating ensures that pipelines remain in place on the seabed, reducing the likelihood of movement that can lead to leaks or breaks.

- Corrosion Resistance Concrete acts as a protective barrier against corrosive marine environments. This reduces maintenance costs and extends the lifespan of pipelines.

- Enhanced Impact Protection The coating provides a robust defense against mechanical impacts, such as those caused by debris or falling objects, which is particularly vital during installation and operation.

- Economic Efficiency While the initial application of CWC may have associated costs, the long-term benefits, including reduced maintenance and downtime, make it a cost-effective solution.

The Manufacturing Process

The manufacturing process of concrete weight coating typically involves several steps

1. Surface Preparation The pipeline's surface is cleaned and prepared to ensure proper adhesion of the concrete.

2. Coating Application Concrete is then applied to the pipeline using specialized equipment. The coating thickness can be customized based on the specific requirements of the project.

3. Curing After application, the concrete must cure properly to achieve the desired strength and durability. This process may take several days depending on environmental conditions.

4. Quality Control Inspection and testing are conducted to ensure the coating meets industry standards and the project's specifications.

Conclusion

Concrete weight coating is a critical process that plays a vital role in the safety and efficiency of various pipeline applications, especially in the challenging offshore environment. With benefits such as increased stability, corrosion resistance, and economic efficiency, CWC is a preferred solution for industries needing reliable and durable pipeline systems. As the demand for energy continues to grow, the importance of innovative solutions like concrete weight coating will only increase, reinforcing its position as a cornerstone in modern infrastructure development.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

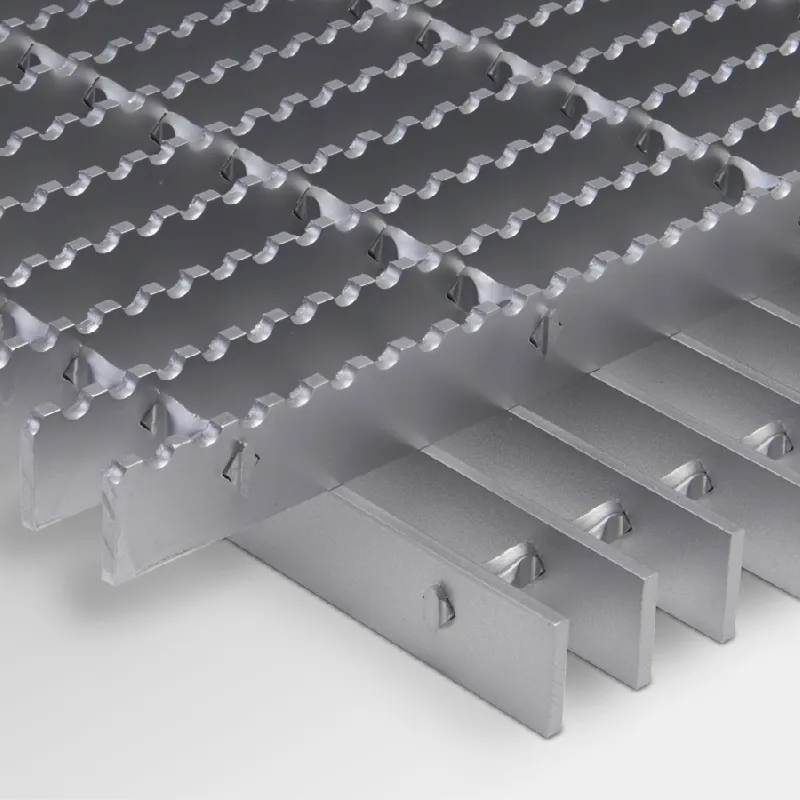

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025