- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Importance of Shale Shaker Screen Mesh in Drilling Applications and Efficiency

Understanding Shale Shaker Screen Mesh Essential Components of Drilling Operations

Shale shakers are vital equipment used in the oil and gas industry, particularly in drilling operations. These devices play a critical role in separating drilling fluid from cuttings, ensuring the efficient and effective extraction of resources. A central element of the shale shaker is the shaker screen mesh, which directly impacts the performance and efficiency of the drilling process. In this article, we will explore the significance of shale shaker screen mesh and the factors to consider when selecting the appropriate type.

What is Shale Shaker Screen Mesh?

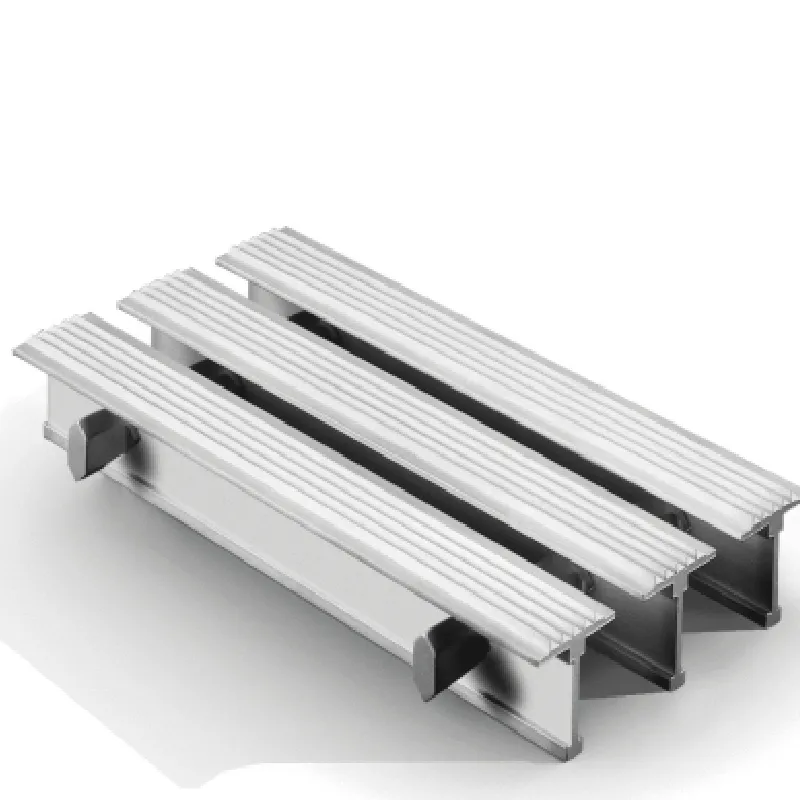

Shale shaker screen mesh is a filter component that allows drilling fluids to pass through while retaining solid particles, such as rock cuttings and other debris. The design and material of these screens vary, tailored to meet the specific requirements of different drilling applications. Made from durable materials like stainless steel, composite, or polyester, the mesh screens are engineered to withstand the harsh conditions encountered during drilling operations.

Types of Shaker Screen Mesh

There are several types of shaker screens, each designed for specific tasks

. The most common classifications include1. API Screens These screens adhere to the American Petroleum Institute (API) standards, which dictate the size and configuration of mesh openings. API screens are categorized by their mesh size, identified by a designation number (e.g., API 80, API 100), representing the number of threads per linear inch. The API system helps maintain consistent performance across various drilling environments.

2. Hookstrip Screens Known for their robust design, hookstrip screens feature metal hooks along the edges, which facilitate a secure attachment to the shaker deck. These screens are typically used in high-volume applications due to their strength and ability to handle large volumes of drilling fluid.

3. Composite Screens Composed of both metal and composite materials, these screens offer superior durability and resistance to wear and tear. They are often lighter than traditional metal screens, enhancing overall shaker performance and efficiency while retaining the necessary strength for extended use.

shale shaker screen mesh

Factors Influencing Screen Selection

Selecting the appropriate shaker screen mesh is crucial for optimizing drilling operations. Several factors must be considered, including

1. Mesh Size The mesh size directly impacts the separation efficiency. A finer mesh will capture smaller particles but may reduce fluid flow rates. Conversely, a coarser mesh allows for higher flow rates but may let larger particles slip through. The right balance must be achieved based on the specific drilling conditions.

2. Flow Rate Understanding the flow rate of the drilling fluid is essential for selecting the right mesh. High flow rates may require larger openings to prevent clogging, while lower flow rates can benefit from finer meshes for better filtration.

3. Drilling Environment The type of formation being drilled (soft, hard, clay-rich, etc.) influences the choice of screen mesh. Different formations generate different sizes of cuttings, which affects which mesh will be most effective.

4. Cost and Durability While cost is always a consideration, the longevity and durability of the screen must be evaluated. Investing in higher-quality screens may result in better performance and reduced replacement frequency over time.

Conclusion

In summary, shale shaker screen mesh is a critical component of successful drilling operations. Understanding the various types of screens, their characteristics, and the factors influencing their selection is essential for optimizing performance. As the demand for efficient resource extraction continues to grow, the importance of selecting the right shaker screen mesh cannot be overstated. By making informed decisions, operators can enhance their drilling efficiency, reduce costs, and ultimately contribute to the sustainable development of the oil and gas industry.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025