- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

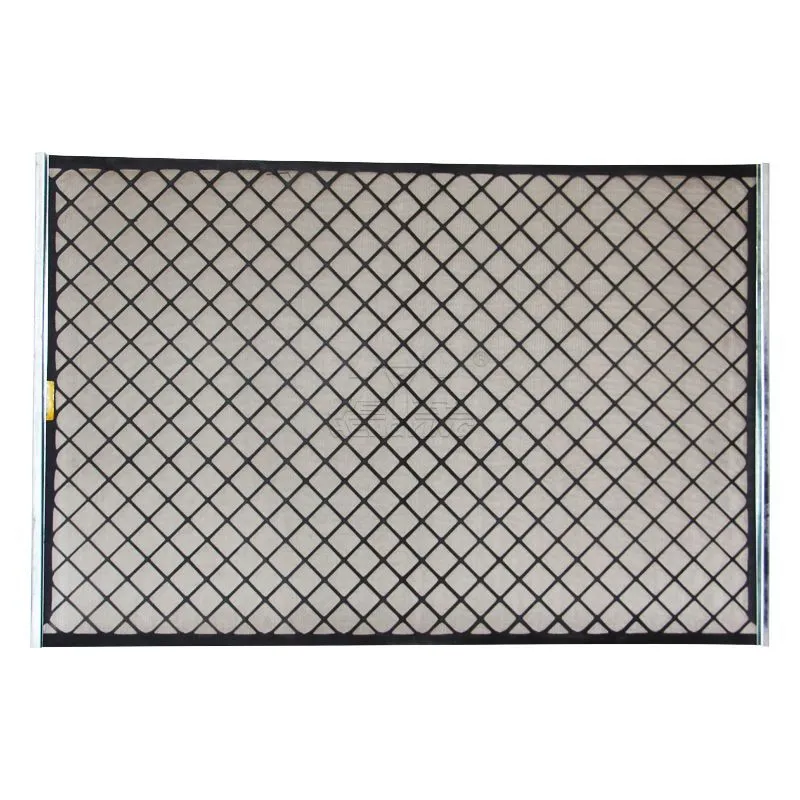

Woven Steel Pipe Design for Enhanced Durability and Strength Applications

The Importance and Applications of Steel Pipe Winding Mesh

Steel pipe winding mesh is a sophisticated material that has garnered considerable attention in various industries due to its strength, durability, and versatility. This specialized mesh is designed by wrapping steel wire around a series of pipes, creating a robust structure that can be utilized in numerous applications. As the demand for high-performance materials increases, understanding the advantages and uses of steel pipe winding mesh becomes essential.

Composition and Manufacturing

Steel pipe winding mesh is typically made from high-quality stainless or carbon steel, providing excellent resistance to corrosion and wear. The manufacturing process involves carefully winding steel wire around pipes using advanced machinery, ensuring tight adhesion and structural integrity. This method not only enhances the mechanical properties of the mesh but also allows for customization in terms of size, shape, and mesh density, making it suitable for various applications.

Key Advantages

1. Strength and Durability One of the most significant attributes of steel pipe winding mesh is its impressive strength. The interwoven design distributes loads evenly, making it resistant to deformation and damage. This durability is critical in environments where heavy weights or harsh conditions are present.

2. Corrosion Resistance Depending on the type of steel used, the mesh can offer exceptional resistance to rust and corrosion. This is particularly important in industries like construction and oil and gas, where exposure to moisture and chemicals is common.

3. Lightweight Despite its strength, steel pipe winding mesh is surprisingly lightweight. This characteristic aids in reducing the overall weight of structures while maintaining the necessary integrity and support, making it easier and more cost-effective to transport and install.

4. Customizability With advancements in technology, steel pipe winding mesh can be tailored to meet specific requirements. Whether it’s a unique size, shape, or configuration, manufacturers can create mesh products that comply with client specifications, making it applicable across diverse industries.

steel pipe winding mesh

Applications

The versatility of steel pipe winding mesh opens doors to countless applications

- Construction and Engineering In civil engineering, steel pipe winding mesh can be used in bridge construction, retaining walls, and other structural components. The mesh supports load-bearing applications while allowing for the natural flow of water in drainage systems.

- Infrastructure Roadworks and railroads often employ steel pipe winding mesh for stabilization and reinforcement purposes. Its ability to withstand heavy traffic loads and environmental wear makes it an ideal choice for infrastructure development.

- Agriculture In agricultural settings, steel pipe winding mesh is used for fencing, trellises, and other support structures. Its strength ensures longevity, protecting crops while promoting healthy growth.

- Oil and Gas The oil and gas industry utilizes steel pipe winding mesh for various applications, including in pipelines and storage tanks. Its resistance to harsh chemicals and environmental degradation is paramount in maintaining safety and efficiency in these operations.

- Mining In mining operations, steel pipe winding mesh is instrumental in supporting tunnels and caverns, ensuring safety for workers while providing a robust framework that can resist dynamic forces.

Conclusion

In summary, steel pipe winding mesh stands out as a critical material in numerous fields due to its unique characteristics and adaptability. Its strength, corrosion resistance, lightweight nature, and customizability make it a preferred choice in construction, agriculture, and industrial applications. As industries continue to evolve and seek innovative solutions, the role of steel pipe winding mesh will undoubtedly expand, driving advancements in engineering and material sciences. With ongoing research and development, we can expect to see even more exciting applications for this versatile material in the future.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025