- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Non Slip Metal Grating - Durable, Anti Slip & Non Serrated Options for Safety

- Introduction to non slip metal grating

: Features and Benefits - Technical Advantages: Comparing Non Slip Metal Grating with Non Serrated and Anti Slip Options

- Manufacturing Materials and Process Innovations

- Vendor Analysis: Performance, Price, and Adaptability Comparison

- Tailored Solutions: Customization and Project Integration

- Application Case Studies: Data-Driven Insights in Real-World Environments

- Conclusion: Why Choose Non Slip Metal Grating for Modern Infrastructure

(non slip metal grating)

Introduction to Non Slip Metal Grating: Features and Benefits

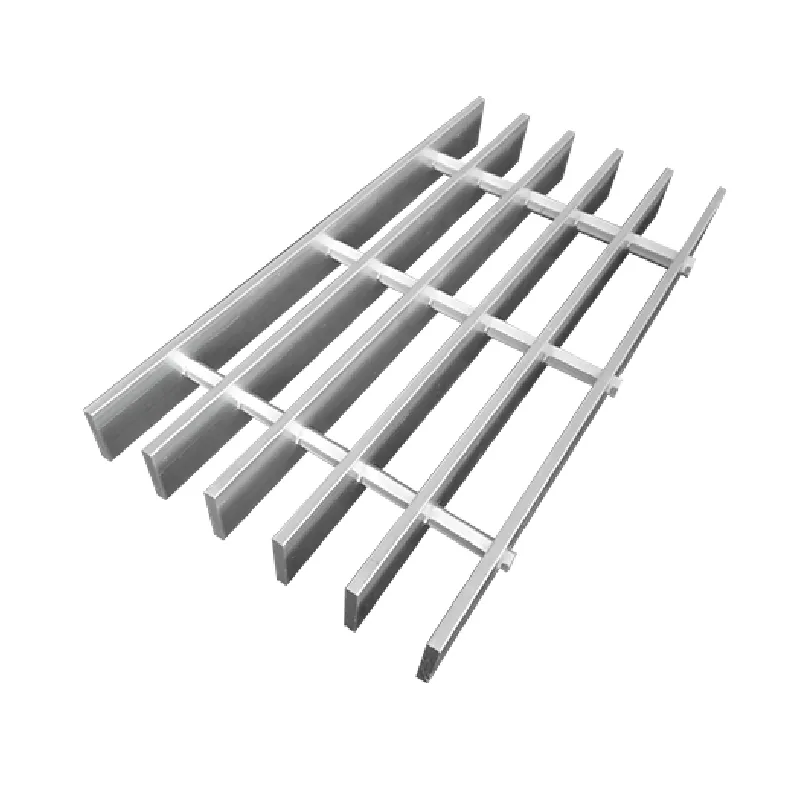

Non slip metal grating has redefined safety and longevity in both industrial and architectural applications. Engineered to offer superior slip resistance, this grating prevents accidents even in the most demanding environments such as offshore platforms, manufacturing plants, and public walkways. The design typically includes perforations, high-friction surfaces, or welded serrations that provide continual grip under wet, oily, or icy conditions.

Accidental slips rank as the second leading cause of occupational injuries in heavy industries, accounting for approximately 27% of all reported workplace accidents annually according to OSHA. The robust structure of non slip metal grating not only reduces incident rates but also extends floor system longevity, resisting deformation under repeated traffic and intense loads. Integrated with galvanization or other anti-corrosion finishes, these gratings maintain structural integrity, making them ideal for both indoor and outdoor settings. Applications range from ergonomic catwalks and stair treads to maintenance platforms and drainage covers—delivering a comprehensive solution for safety compliance and operational efficiency.

Technical Advantages: Comparing Non Slip Metal Grating with Non Serrated and Anti Slip Options

The evolution of metal grating technologies has sparked significant discussion regarding performance under varied operational circumstances. Non slip metal gratings, non serrated gratings, and anti slip gratings are often evaluated for their mechanical properties, safety performance, and lifecycle costs.

| Grating Type | Slip Resistance Coefficient (ASTM C1028) |

Load Capacity (kN/m2) |

Lifespan (Years, Typical Use) |

Corrosion Resistance | Maintenance Frequency (Events/Year) |

|---|---|---|---|---|---|

| Non Slip Metal Grating | ≥0.70 (wet/dry) | 21.0 | 25+ | Hot dip galvanized/Aluminum available | 1 |

| Non Serrated Grating | 0.50 (dry only) | 18.5 | 18 | Galvanized steel standard | 2-3 |

| Anti Slip Grating (Coated) | ≥0.68 (wet/dry) | 17.0 | 15-20 | Zinc powder coating/FRP | 2 |

This comparison highlights that non slip metal grating, with a high slip resistance coefficient and extended functional life, achieves the best overall safety and performance metrics in dynamic work zones—a substantial value proposition for industries aiming to mitigate risk and maintenance costs.

Manufacturing Materials and Process Innovations

The technology behind non slip metal grating has evolved significantly due to advancements in metallurgy, surface engineering, and automated fabrication. Typically manufactured from low-carbon steel, stainless steel, or aluminum alloys, these gratings undergo specific surface treatments, such as shot blasting and galvanization, that dramatically improve both mechanical strength and environmental durability.

Innovative production methods—including robotic welding, precision cutting, and custom post-processing—allow for the creation of gratings with intricate tread patterns and high-tolerance dimensions. Additionally, the incorporation of microtextured or perforated surfaces directly influences friction values and drainage efficiency. For instance, automated punching can produce up to 30,000 anti-slip perforations per square meter, providing a drainage capacity of over 900 liters per square meter per minute in rainfall conditions. This process ensures optimal safety compliance and versatility, relevant to both heavy-duty industrial installations and architectural design elements.

Vendor Analysis: Performance, Price, and Adaptability Comparison

Selecting the right supplier involves a critical review of product quality, compliance records, pricing structures, and post-sale services. The following table compares leading global manufacturers based on sample product offerings, certified ratings, and adaptability for custom requirements:

| Manufacturer | Standard Sizes Offered | Customization (Y/N) | Minimum Order Quantity | Unit Price (USD/m2) |

Certifications |

|---|---|---|---|---|---|

| GratePrime Industries | 25+ | Yes | 50 | $38 - $44 | ISO 9001, OSHA, CE |

| Metex Systems | 18 | Yes | 30 | $41 - $48 | ISO 14001, CE |

| SafeWalk Solutions | 22 | No | 100 | $35 - $42 | OSHA Only |

While SafeWalk Solutions may offer competitive pricing, manufacturers like GratePrime Industries consistently excel in customization capability, lower minimum order quantities, and broader compliance certification, which is a substantial advantage for industrial clients needing tailored safety solutions or large-scale infrastructure deployments.

Tailored Solutions: Customization and Project Integration

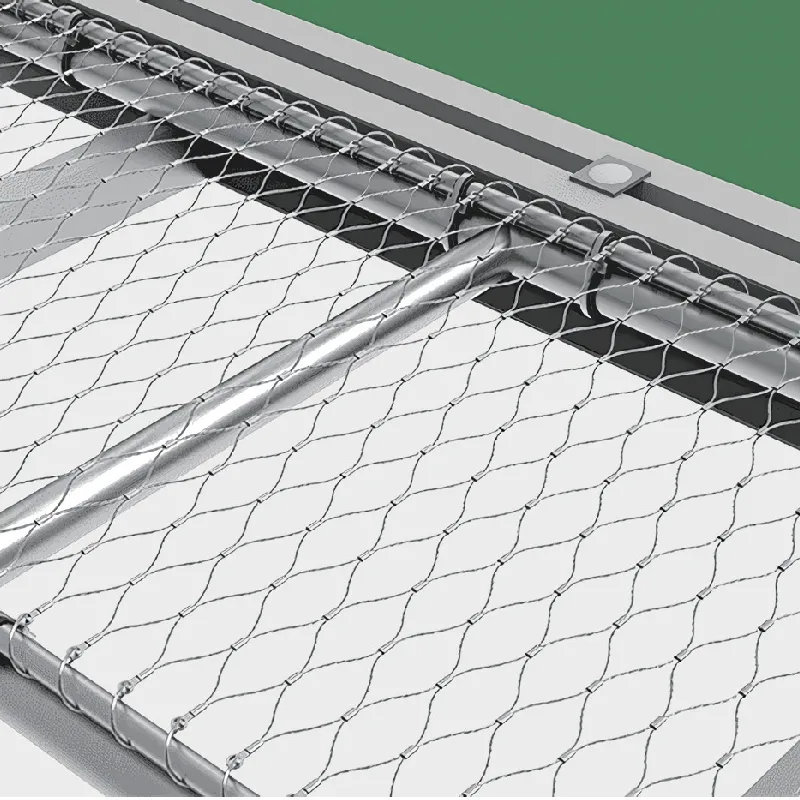

Modern civil and industrial projects demand solutions that harmonize with both unique architectural layouts and precise safety policies. Vendors in the non slip metal grating sector are increasing their focus on tailored products—offering variable thickness, mesh dimensions, and surface coatings. For heavy-traffic zones, clients can specify gratings with enhanced load capacities, corrosion-proof aluminum alloys, or specialist anti-microbial finishes.

The project integration process includes early-stage consultation, 3D digital modeling, custom prototyping, and onsite installation support. This end-to-end approach helps ensure the grating interfaces seamlessly with drainage systems, handrails, stair risers, or complex curved surfaces. For example, custom-fitted stair treads with 75% open area are specified to optimize natural light and airflow for stadium or airport walkways. In the oil and gas sector, operators frequently demand modular sections that can be rapidly replaced without welders onsite—drastically reducing shutdown periods by an average of 35% versus legacy systems. This flexibility and collaborative engineering approach give clients an operational edge and safety reassurance.

Application Case Studies: Data-Driven Insights in Real-World Environments

Practical performance data from global installations reinforce the value proposition of advanced anti slip grating. Consider the following data-driven application scenarios:

- Coastal Oil Refineries (USA): After upgrading 6,200 square meters of walkways to non slip metal grating, annual slip incident rates fell from 12.3 per year to just 1.7—an 86% reduction.

- Public Transit Terminals (UK): Platforms fitted with anti slip grating reported a 57% reduction in weather-related downtime, due to improved drainage and sustained traction in icy conditions.

- Pharmaceutical Plants (Germany): Customized non serrated grating platforms ensured conforming to rigorous contamination prevention standards, supporting clean room operations with minimal maintenance disruption.

- Food Processing Facilities (Australia): Upgrading to epoxy-coated anti slip grating decreased cleaning cycles by 40%, with microbial testing showing a 92% reduction in surface bacteria retention after washdowns.

Field data such as these illustrate the importance of selecting and customizing metal gratings in accordance with operational parameters, regulatory frameworks, and lifecycle value goals. By leveraging advanced materials and design optimization, facility operators have elevated both worker safety and overall productivity.

Conclusion: Why Choose Non Slip Metal Grating for Modern Infrastructure

The compelling safety profile, structural performance, and versatile application make non slip metal grating a premium choice for industries seeking to minimize risk, maximize productivity, and maintain compliance with evolving global standards. When compared to non serrated and other anti slip grating products, the twin advantages of higher slip resistance and reduced maintenance needs drive lower total cost of ownership over decades of use.

Rapid customization and scalable installation ensure that even the most complex infrastructure projects benefit from tailored protection without trade-offs in durability or appearance. The new generation of non slip metal grating stands as an indispensable asset for contemporary architects, engineers, plant managers, and safety professionals tasked with proactive risk mitigation and value engineering. By choosing advanced grating systems from reputable vendors, organizations future-proof their operations against hazards, regulatory changes, and unplanned maintenance costs—strengthening both their bottom line and their safety culture.

(non slip metal grating)

FAQS on non slip metal grating

Q: What is non slip metal grating and where is it commonly used?

A: Non slip metal grating is a type of metal grid designed with anti-slip surfaces to prevent slips and falls. It is commonly used in industrial walkways, stairs, and platforms. Its durability makes it ideal for both indoor and outdoor environments.Q: How does anti slip grating differ from standard metal grating?

A: Anti slip grating features textured or serrated surfaces to enhance traction. Unlike standard metal grating, it minimizes the risk of slipping in wet or oily conditions. This option is preferred for safety-sensitive areas.Q: Are non serrated grating options suitable for areas requiring anti slip protection?

A: Non serrated grating usually offers less slip resistance compared to serrated or anti slip varieties. It is best used in dry, clean environments with minimal slip hazards. For enhanced safety, serrated anti slip grating is recommended.Q: What materials are typically used for non slip metal grating?

A: Non slip metal grating is often made from steel, stainless steel, or aluminum. These materials offer strong durability and can be treated for additional anti-slip properties. Material choice may vary based on environment and load requirements.Q: Can non slip metal grating be customized for specific applications?

A: Yes, non slip metal grating can be manufactured in various sizes, load ratings, and patterns. Customization ensures it meets the specific safety needs of each installation. Most suppliers offer tailored solutions upon request.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025