- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فبراير . 01, 2025 03:49

Back to list

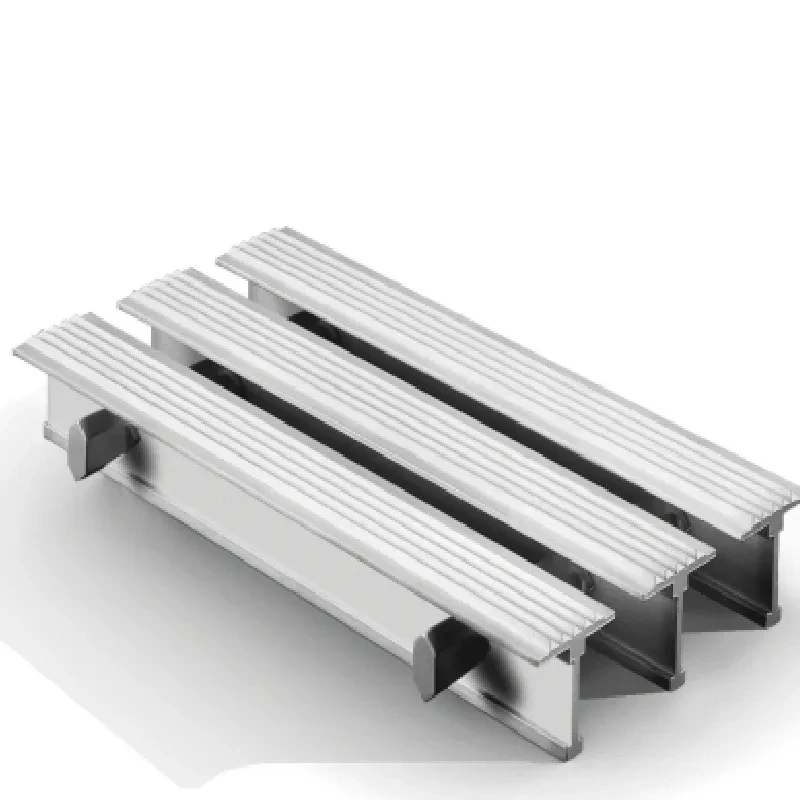

walkway grates

Industrial floor grates play a crucial role in maintaining safety, efficiency, and cleanliness in various commercial and industrial settings. As an essential component in facilitating optimal workflow, understanding the distinctive aspects of industrial floor grates can immensely benefit industries ranging from manufacturing plants to sewage treatment facilities.

When it comes to installation, industrial floor grates offer versatility and flexibility. They can be customized to fit specific requirements of a facility, including varying sizes, shapes, and load-bearing capacities. This adaptability ensures that businesses can optimize floor spacing and layout, contributing to a more streamlined operational flow. Furthermore, easy-to-install features allow minimal disruption during initial setup, contributing to overall cost savings on labor and time. Besides functionality, the maintenance of industrial floor grates is straightforward. Most grates require minimal upkeep, only needing periodic checks and cleaning to maintain optimal performance. Their durable materials resist rust and decay, ensuring a long service life and reducing the frequency and cost of replacements. Such ease of maintenance can significantly contribute to cost efficiency and operational sustainability over time. Choosing the right industrial floor grate involves assessing specific industry needs and conditions. Factors such as load requirements, exposure to corrosive substances, and necessary hygiene levels play essential roles in determining the optimal material and design. Consulting with manufacturers or industry experts can provide insights into the best configurations, ensuring that the chosen solution aligns perfectly with both immediate and future operational demands. Ultimately, investing in high-quality industrial floor grates can lead to enhanced workplace safety, improved operational efficiency, and long-term financial benefits. For business owners and facility managers, prioritizing these components can lead to a safer, cleaner, and more productive working environment, underscoring the importance of carefully selecting floor grates tailored to their specific industrial needs.

When it comes to installation, industrial floor grates offer versatility and flexibility. They can be customized to fit specific requirements of a facility, including varying sizes, shapes, and load-bearing capacities. This adaptability ensures that businesses can optimize floor spacing and layout, contributing to a more streamlined operational flow. Furthermore, easy-to-install features allow minimal disruption during initial setup, contributing to overall cost savings on labor and time. Besides functionality, the maintenance of industrial floor grates is straightforward. Most grates require minimal upkeep, only needing periodic checks and cleaning to maintain optimal performance. Their durable materials resist rust and decay, ensuring a long service life and reducing the frequency and cost of replacements. Such ease of maintenance can significantly contribute to cost efficiency and operational sustainability over time. Choosing the right industrial floor grate involves assessing specific industry needs and conditions. Factors such as load requirements, exposure to corrosive substances, and necessary hygiene levels play essential roles in determining the optimal material and design. Consulting with manufacturers or industry experts can provide insights into the best configurations, ensuring that the chosen solution aligns perfectly with both immediate and future operational demands. Ultimately, investing in high-quality industrial floor grates can lead to enhanced workplace safety, improved operational efficiency, and long-term financial benefits. For business owners and facility managers, prioritizing these components can lead to a safer, cleaner, and more productive working environment, underscoring the importance of carefully selecting floor grates tailored to their specific industrial needs.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025