- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يناير . 19, 2025 01:41

Back to list

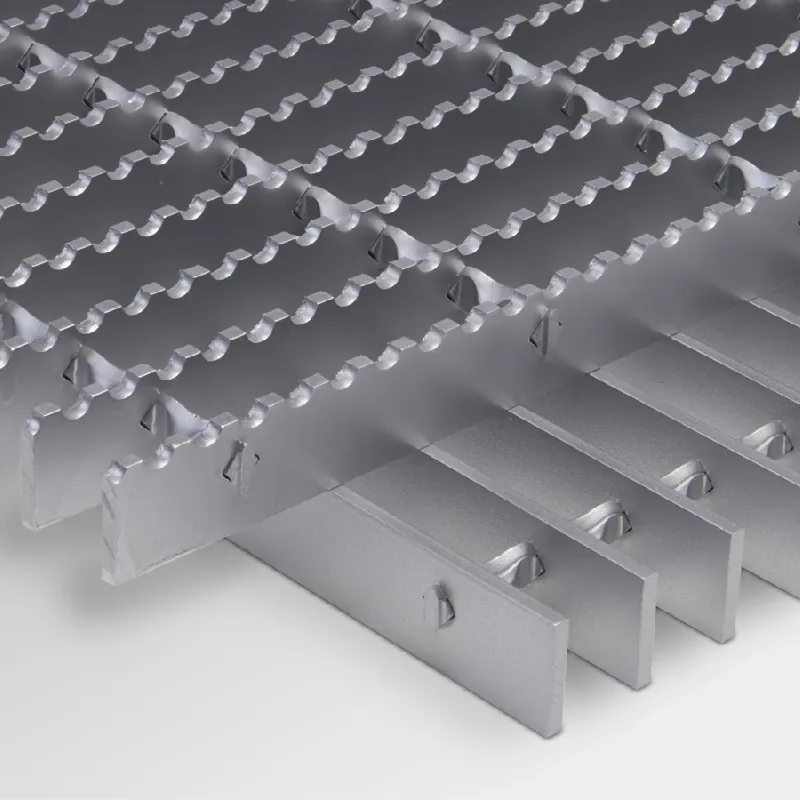

galvanized metal grating

Galvanized metal grating is an essential component across various industries, revered for its durability, strength, and versatility. In the world of construction and industrial applications, selecting the right material can make a difference in performance and longevity. This article aims to provide an in-depth understanding of galvanized metal grating, ensuring that you make informed decisions backed by expertise and reliable data.

Galvanized metal grating is also lauded for its ease of installation and maintenance. The robustness imparted by the galvanization process means that these gratings can be quickly and securely installed, reducing downtime and labor costs. Additionally, the reduced maintenance is a significant upside for organizations looking to optimize operational efficiency. With a straightforward cleaning process and minimal maintenance required, galvanized grating offers a hassle-free, long-term solution. In terms of authority, it is essential to highlight how galvanized metal grating meets and often exceeds industry standards. Regulations and standards play a crucial role in ensuring that materials used in construction and industrial applications are safe and effective. Galvanized grating regularly meets specifications set by organizations such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), providing assurance of its quality and performance. Trustworthiness in any construction material is critical, and galvanized metal grating has a proven track record. Its widespread use across numerous sectors serves as a testament to its reliability. When projects demand materials that provide both reassurance and superior performance, galvanized metal grating is often at the forefront. Stakeholders, ranging from government entities to private sector operators, often rely on this material for projects requiring stringent safety and performance standards. Finally, incorporating galvanized metal grating into your project or facility can also contribute to sustainability goals. The steel used in these gratings is often recycled, and the galvanization extends the lifecycle of the material. This element of sustainability is a growing consideration for businesses and industries aiming to lessen their environmental impact. By choosing galvanized metal grating, entities can participate in a larger movement towards responsible consumption and material usage. In conclusion, galvanized metal grating stands out as a prime choice for projects that demand durability, flexibility, and reliability. With its robust protective qualities and proven performance, investing in galvanized metal grating is a step towards enhancing structural integrity and ensuring long-term success. Whether you are an engineer, architect, or project manager, the informed choice of galvanized metal grating is bound to yield substantial benefits, substantiated by its longstanding authority and trustworthiness in the industry.

Galvanized metal grating is also lauded for its ease of installation and maintenance. The robustness imparted by the galvanization process means that these gratings can be quickly and securely installed, reducing downtime and labor costs. Additionally, the reduced maintenance is a significant upside for organizations looking to optimize operational efficiency. With a straightforward cleaning process and minimal maintenance required, galvanized grating offers a hassle-free, long-term solution. In terms of authority, it is essential to highlight how galvanized metal grating meets and often exceeds industry standards. Regulations and standards play a crucial role in ensuring that materials used in construction and industrial applications are safe and effective. Galvanized grating regularly meets specifications set by organizations such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), providing assurance of its quality and performance. Trustworthiness in any construction material is critical, and galvanized metal grating has a proven track record. Its widespread use across numerous sectors serves as a testament to its reliability. When projects demand materials that provide both reassurance and superior performance, galvanized metal grating is often at the forefront. Stakeholders, ranging from government entities to private sector operators, often rely on this material for projects requiring stringent safety and performance standards. Finally, incorporating galvanized metal grating into your project or facility can also contribute to sustainability goals. The steel used in these gratings is often recycled, and the galvanization extends the lifecycle of the material. This element of sustainability is a growing consideration for businesses and industries aiming to lessen their environmental impact. By choosing galvanized metal grating, entities can participate in a larger movement towards responsible consumption and material usage. In conclusion, galvanized metal grating stands out as a prime choice for projects that demand durability, flexibility, and reliability. With its robust protective qualities and proven performance, investing in galvanized metal grating is a step towards enhancing structural integrity and ensuring long-term success. Whether you are an engineer, architect, or project manager, the informed choice of galvanized metal grating is bound to yield substantial benefits, substantiated by its longstanding authority and trustworthiness in the industry.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025