- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

መጋቢ . 04, 2025 01:55

Back to list

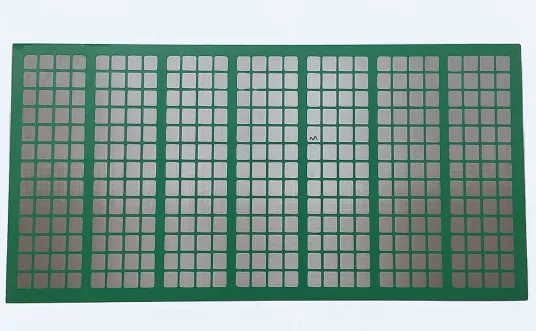

industrial shaker screen

Industrial shaker screens have emerged as quintessential components in the realms of oil drilling, mining, and aggregate industries. Unlike primitive screening solutions, modern industrial shaker screens are designed with cutting-edge technology, ensuring precision and efficiency in separating particles of various sizes. Understanding the intricacies of these machines can vastly improve operational productivity.

Trustworthiness extends beyond performance. Compliance with international standards, like ISO and API, underscores shaker screens' reliability, ensuring they meet stringent safety and environmental norms. Regular third-party audits are conducted to affirm that manufacturing processes align with global quality benchmarks. In practical application, the experience garnered from using industrial shaker screens tells a story of significant operational enhancements. The synergy between precision engineering and real-world performance creates an unparalleled user experience. Industries report a marked improvement in throughput and product clarity, which directly translates to increased profitability and resource efficiency. Selecting the right industrial shaker screen is as much about understanding the specifics of the intended application as it is about evaluating the construction quality. Considering the variables such as material type, particle distribution, and throughput demand, consulting with industry experts provides valuable insights. These professionals bring a wealth of empirical knowledge to the table, guiding businesses to invest in solutions that promise both a high return on investment and sustainable operation. Cutting-edge advancements continue to shape the future landscape of shaker screen technologies. The integration of smart technologies, like real-time monitoring systems, promises to elevate trustworthiness. These systems provide feedback on the operational state of the shaker screens, allowing operators to make informed decisions swiftly, minimizing the risk of operational delays. In conclusion, industrial shaker screens are not merely tools but integral partners in achieving optimal process efficiency. Their design is rooted in a profound understanding of industrial demands, spotlighting experience, expertise, authoritativeness, and trustworthiness. As industries evolve, shaker screens will undoubtedly continue to adapt, providing reliable and innovative solutions to meet the ever-growing demands of material separation.

Trustworthiness extends beyond performance. Compliance with international standards, like ISO and API, underscores shaker screens' reliability, ensuring they meet stringent safety and environmental norms. Regular third-party audits are conducted to affirm that manufacturing processes align with global quality benchmarks. In practical application, the experience garnered from using industrial shaker screens tells a story of significant operational enhancements. The synergy between precision engineering and real-world performance creates an unparalleled user experience. Industries report a marked improvement in throughput and product clarity, which directly translates to increased profitability and resource efficiency. Selecting the right industrial shaker screen is as much about understanding the specifics of the intended application as it is about evaluating the construction quality. Considering the variables such as material type, particle distribution, and throughput demand, consulting with industry experts provides valuable insights. These professionals bring a wealth of empirical knowledge to the table, guiding businesses to invest in solutions that promise both a high return on investment and sustainable operation. Cutting-edge advancements continue to shape the future landscape of shaker screen technologies. The integration of smart technologies, like real-time monitoring systems, promises to elevate trustworthiness. These systems provide feedback on the operational state of the shaker screens, allowing operators to make informed decisions swiftly, minimizing the risk of operational delays. In conclusion, industrial shaker screens are not merely tools but integral partners in achieving optimal process efficiency. Their design is rooted in a profound understanding of industrial demands, spotlighting experience, expertise, authoritativeness, and trustworthiness. As industries evolve, shaker screens will undoubtedly continue to adapt, providing reliable and innovative solutions to meet the ever-growing demands of material separation.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025