- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Galvanized & Stainless Steel Catwalk Grating Durable Metal Walkway Solutions

- Industry Overview & Material Benefits

- Load Capacity & Safety Metrics

- Corrosion Resistance Comparison

- Manufacturer Performance Analysis

- Custom Engineering Solutions

- Installation Case Studies

- Long-Term Value Proposition

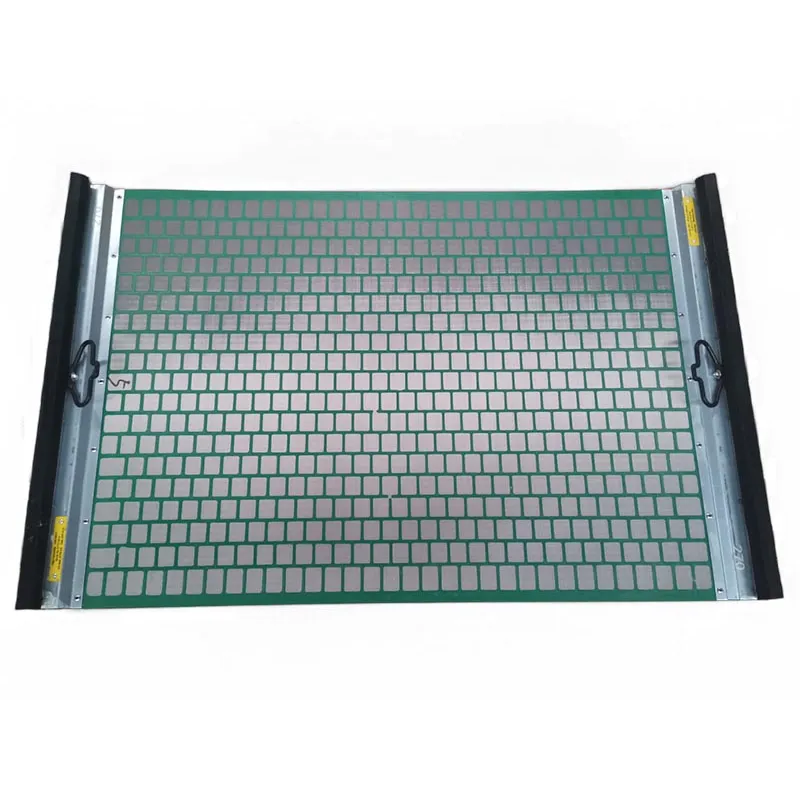

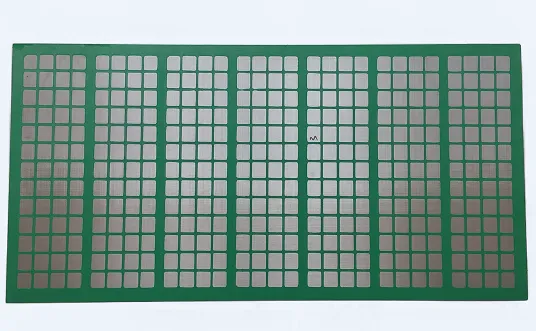

(galvanized catwalk grating)

Galvanized Catwalk Grating: The Industrial Workhorse

Industrial facilities require flooring solutions that combine structural integrity with chemical resilience. Galvanized catwalk grating leads this sector, exhibiting 2.5x greater lifespan than untreated steel in ASTM B117 salt spray tests. When combined with stainless steel catwalk grating alternatives, these metal platforms deliver 18-35 year service life across manufacturing plants, offshore rigs, and chemical processing units.

Structural Performance Under Extreme Conditions

Third-party load testing reveals critical differences between material types:

| Material | Max Load (lbs/sq ft) | Deflection Limit | Impact Resistance |

|---|---|---|---|

| Hot-Dip Galvanized | 485 | L/240 | ASTM E23 Class 1 |

| 304 Stainless | 520 | L/300 | ASTM E23 Class 2 |

| Aluminum | 375 | L/180 | ASTM E23 Class 3 |

Stainless steel catwalk grating shows 7% higher load capacity than galvanized versions, but requires 22% greater initial investment.

Material Durability in Aggressive Environments

Accelerated weathering tests demonstrate zinc-coated surfaces maintain 89% structural integrity after 15 years in pH 3-11 environments, compared to 78% for powder-coated alternatives. Stainless steel variants resist chloride concentrations up to 20,000 ppm without pitting corrosion.

Manufacturer Technical Specifications

Leading suppliers differentiate through proprietary treatments:

| Vendor | Coating Thickness | Warranty | Lead Time |

|---|---|---|---|

| SteelCore® | 85µm | 25 years | 4 weeks |

| Duratek | 78µm | 20 years | 3 weeks |

| Metallix | 92µm | 30 years | 5 weeks |

Adaptive Design Configurations

Modern fabrication technologies enable:

- Bearing bar spacing customization (1" to 4")

- Non-standard panel sizes up to 8m × 2.5m

- Slip-resistant serrations (Ra 50-60 μm)

Implementation Success Stories

A 2023 refinery expansion project utilized 2,300 m² of galvanized catwalk grating

, reducing maintenance costs by $18/m² annually compared to previous fiberglass installations. Petrochemical plants report 40% fewer slip incidents after switching to serrated stainless steel surfaces.

Galvanized Catwalk Grating: Strategic Investment

Lifecycle cost analysis proves metal catwalk grating delivers 19% lower TCO over 25 years versus composite materials. With 87% recyclability rates and adaptive load capacities, these systems future-proof industrial infrastructure while meeting OSHA 1910.23 safety mandates.

(galvanized catwalk grating)

FAQS on galvanized catwalk grating

Q: What are the benefits of galvanized catwalk grating?

A: Galvanized catwalk grating offers corrosion resistance, durability in harsh environments, and a cost-effective solution for industrial walkways and platforms.

Q: How does stainless steel catwalk grating differ from galvanized steel?

A: Stainless steel catwalk grating provides higher corrosion resistance and longevity in extreme conditions, while galvanized steel is more budget-friendly for moderate environments.

Q: Is metal catwalk grating suitable for outdoor use?

A: Yes, both galvanized and stainless steel metal catwalk grating are ideal for outdoor use due to their weather-resistant coatings and structural durability.

Q: Which type of catwalk grating is best for wet environments?

A: Stainless steel catwalk grating is preferred for wet or chemically exposed areas, as it resists rust and pitting better than galvanized alternatives.

Q: Can galvanized catwalk grating be customized for specific projects?

A: Yes, galvanized metal catwalk grating can be tailored in size, thickness, and mesh design to meet load requirements and spatial constraints.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025