- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Optimizing Concrete Weight Coating for Pipeline Stability and Protection Systems

Understanding Concrete Weight Coating for Pipes An Essential Overview

Concrete weight coating (CWC) is an essential process used in the oil and gas industry to protect submarine pipelines from external forces and provide necessary stability. This technique involves applying a layer of concrete to the surface of the pipes, ensuring they are adequately weighed down when submerged underwater. This article delves into the importance, application, and benefits of CWC, as well as the role of mesh in enhancing the process.

The Importance of Concrete Weight Coating

Submarine pipelines are critical for the transportation of oil, gas, and other resources across bodies of water. When these pipelines are laid on the seabed, they can be subject to currents, shifting sediments, and other environmental challenges. Without adequate weight and protection, the pipelines could be vulnerable to displacement, damage, or even total failure, which can lead to significant environmental and economic consequences.

CWC serves to provide the necessary weight to keep pipelines stable on the seabed, preventing uplift or lateral movement

. Additionally, it offers physical protection to the pipeline from external abrasions and impacts, such as those caused by fishing activities or underwater construction.The Application Process

The application of concrete weight coating typically involves several steps. Initially, the pipes are cleaned and prepared to ensure a smooth surface for the coating. This preparation can include sandblasting or pressure washing, removing any rust, dirt, or debris. Next, the pipes are transported to a coating facility where they undergo the coating process.

concrete weight coating pipe mesh

Once prepared, a layer of concrete is applied to the pipe, either via direct pouring or a specialized spraying technique. This layer can be customized in thickness, depending on specific project requirements. After the concrete application, it is essential to allow adequate curing time. This phase ensures that the coating properly adheres to the pipe and reaches its full strength before installation.

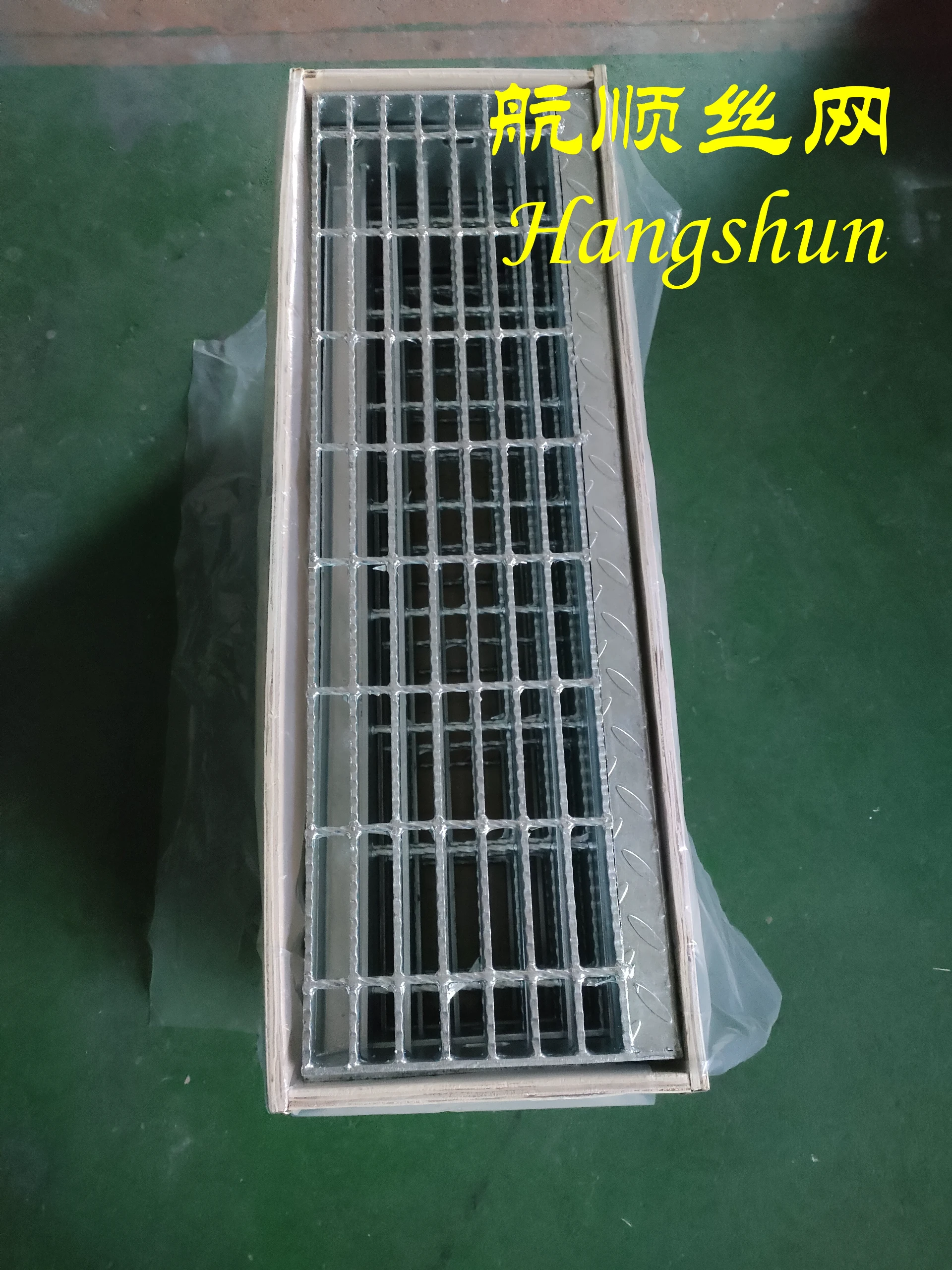

Mesh A Structural Enhancement

In many cases, a mesh may be incorporated into the concrete weight coating process. This is typically made from steel, providing increased structural integrity and enhancing the bonding of the concrete to the pipe. The mesh acts like a reinforcement grid, distributing stresses more evenly and preventing cracks in the concrete during application or after exposure to varying environmental conditions.

The use of mesh is particularly relevant in areas with higher risks of mechanical stress or where the pipeline may be subject to dynamic forces. By incorporating this additional layer of support, the overall durability and life expectancy of the concrete-coated pipes can be significantly improved, thereby ensuring continued safety and functionality.

Benefits of Concrete Weight Coating

The advantages of concrete weight coating for pipelines are numerous. Firstly, the stability provided by the added weight prevents shifting or floating, ensuring the pipeline remains in its intended position over time. Secondly, the protective nature of the concrete coating guards against environmental wear and potential damage, contributing to the longevity of the pipeline. Furthermore, the incorporation of mesh enhances this protection, making the coating more robust and resistant to various stresses.

In conclusion, concrete weight coating is an indispensable component of modern pipeline construction and installation, especially in marine applications. By ensuring stability, providing protection, and enhancing structural integrity, CWC plays a vital role in safeguarding our vital energy resources. As industries continue to evolve and demand more from their infrastructure, innovations in techniques, such as the utilization of mesh within the coating process, will undoubtedly shape the future of pipeline technology.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025