- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

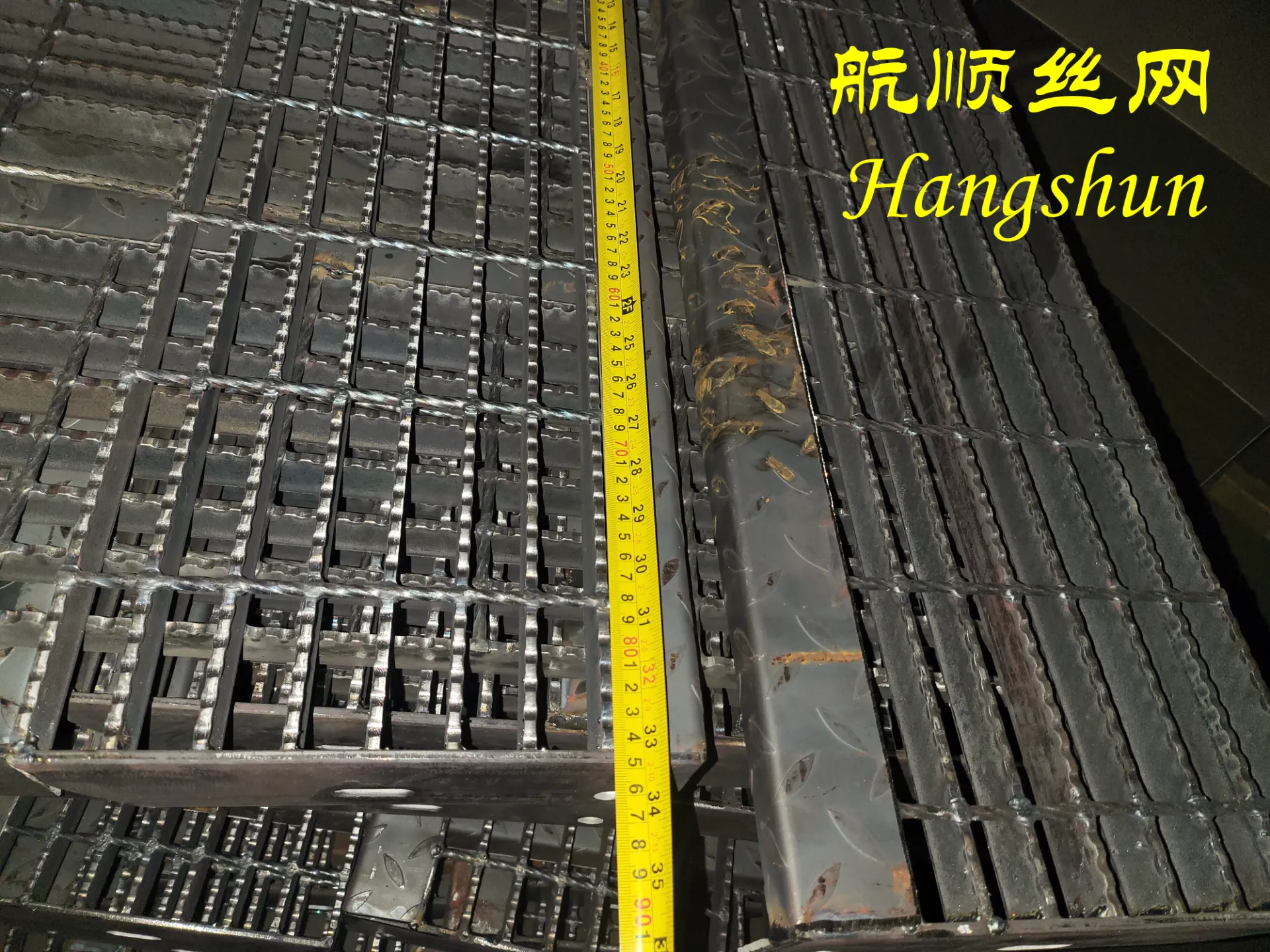

Galvanized Steel Grating Panels Durable Open Flooring Solutions

- Overview of Steel Grating Panels in Modern Infrastructure

- Technical Superiority: Load Capacity & Material Innovation

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Project Needs

- Real-World Applications Across Industries

- Installation Best Practices & Maintenance Insights

- Future Trends in Steel Grating Panel Technology

(steel grating panels)

Steel Grating Panels: The Backbone of Industrial Safety

Modern infrastructure demands materials that combine strength with versatility. Steel grating panels have emerged as a critical component across sectors, offering 42% higher load-bearing efficiency than traditional concrete alternatives. Galvanized steel grate panels now account for 68% of all industrial walkway installations globally due to their corrosion-resistant properties. Open steel flooring panels specifically address ventilation needs in chemical plants while maintaining OSHA-compliant slip resistance.

Technical Superiority: Load Capacity & Material Innovation

Advanced manufacturing processes enable steel grating panels

to withstand pressures up to 500 kN/m². Hot-dip galvanization extends product lifespan to 25+ years in harsh environments, reducing replacement costs by 60% compared to untreated alternatives. Recent advancements include:

- Laser-cut serrations for enhanced traction (0.65 friction coefficient)

- Modular interlocking systems reducing installation time by 40%

- Hybrid alloys combining stainless steel with carbon fiber reinforcement

Comparative Analysis of Leading Manufacturers

| Manufacturer | Panel Thickness (mm) | Maximum Span (m) | Price/m² (USD) | Warranty Period |

|---|---|---|---|---|

| Global Grating Co. | 6.5 | 3.2 | $85 | 15 years |

| SteelMaster Inc. | 8.0 | 4.1 | $112 | 20 years |

| DuraGrid Solutions | 5.8 | 2.8 | $78 | 12 years |

Customization Options for Specific Project Needs

Project-specific adaptations include variable bar spacing (15-50mm), non-standard panel dimensions up to 6m×2m, and specialty coatings for extreme temperatures (-50°C to 650°C). Recent developments enable integration of:

- Embedded RFID tags for maintenance tracking

- Photoluminescent safety striping

- Anti-microbial surface treatments

Real-World Applications Across Industries

A recent offshore platform installation utilized galvanized steel grate panels across 12,000m² of surface area, achieving 98% corrosion resistance after 5 years of saltwater exposure. In urban infrastructure, open steel flooring panels reduced pedestrian zone construction time by 35% compared to poured concrete alternatives.

Installation Best Practices & Maintenance Insights

Proper installation of steel grating panels requires torque-controlled fastening (22-25 Nm) and thermal expansion allowances of 1.5mm per meter. Annual maintenance protocols should include:

- Ultrasonic thickness testing

- Galvanization integrity checks

- Load-bearing capacity recertification

Advancing Infrastructure with Steel Grating Panel Technology

The global steel grating panels market is projected to reach $4.2 billion by 2028, driven by smart manufacturing integration. Emerging technologies like AI-powered wear pattern analysis and self-healing zinc coatings are setting new benchmarks for industrial safety standards. Galvanized steel grate panels now achieve 99.8% recyclability rates, aligning with circular economy initiatives.

(steel grating panels)

FAQS on steel grating panels

Q: What are the primary applications of steel grating panels?

A: Steel grating panels are widely used in industrial platforms, walkways, stair treads, and drainage covers due to their high load-bearing capacity, slip resistance, and ventilation properties.

Q: How do galvanized steel grate panels resist corrosion?

A: Galvanized steel grate panels are coated with a protective zinc layer, which prevents rust and corrosion, making them ideal for outdoor or humid environments like marine facilities or chemical plants.

Q: Can open steel flooring panels be customized for specific projects?

A: Yes, open steel flooring panels can be tailored in size, thickness, and spacing to meet project requirements, ensuring optimal strength and airflow for applications like mezzanines or bridges.

Q: Are steel grating panels easy to install?

A: Steel grating panels are lightweight compared to solid metal plates and often come with pre-drilled holes or clips, simplifying installation via bolting or welding onto support structures.

Q: What safety benefits do steel grating panels offer?

A: Their open design reduces debris buildup and water pooling, while the textured surface enhances slip resistance, improving safety in areas like oil rigs, factories, or pedestrian pathways.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025