- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shakerscreen manufacturers

The Importance of Shale Shakers and Their Screens in the Oil and Gas Industry

In the oil and gas industry, the drilling process is integral to accessing underground resources. One of the critical components in this process is the shale shaker, a piece of equipment used to separate drilling fluid from the cuttings generated during drilling. The effectiveness of a shale shaker relies heavily on its screen, which plays a pivotal role in ensuring the efficiency and efficacy of drilling operations. As a result, the demand for shale shaker screen manufacturers has seen a significant rise in recent years.

Understanding Shale Shakers

Shale shakers are vibrating screens designed to remove solid materials from drilling fluid. They provide a continuous flow of fluid while separating unwanted particulates, which helps in maintaining the proper viscosity and density of the drilling mud. By effectively filtering out cuttings, shale shakers prevent them from circulating back into the wellbore, which could lead to complications in drilling operations.

The Role of Screens in Shale Shakers

The screen is the heart of a shale shaker, determining both the separation efficiency and the overall performance of the device. Various screen types and designs are available, such as woven wire mesh, perforated plates, and composite screens. The choice of screen affects the drilling fluid properties, and a well-chosen screen can enhance the life of the shale shaker while optimizing fluid recovery.

Manufacturers offer screens with different mesh sizes to accommodate various drilling conditions. The mesh size influences the cuttings size that can be effectively removed from the drilling fluid. For instance, smaller mesh sizes are typically used for finer solids, while larger openings may be useful for coarser cuttings. The manufacturing process, including the materials and technology used, is crucial to ensure the screens' durability and performance.

Manufacturers in the Market

shale shakerscreen manufacturers

Numerous manufacturers specialize in producing shale shaker screens, each bringing unique technology and design philosophy to the market. Leading companies dedicate extensive resources to research and development to improve screen performance, reduce operational costs, and enhance the lifecycle of the equipment.

Quality is paramount for shale shaker screen manufacturers, as any failure in the screening process can lead to significant issues, such as increased wear on the drilling rig components, reduced drilling efficiency, and potential delays in operation. Manufacturers often comply with stringent industry standards and certifications to ensure their products meet the necessary requirements.

Innovations and Trends

The industry is witnessing several innovative trends aimed at enhancing shale shaker screen efficiency. Advanced materials, such as composite and polyurethane screens, offer higher durability and are more resistant to wear and tear than traditional wire mesh screens. Additionally, manufacturers are exploring automation and the integration of smart technologies to monitor the performance of shale shakers and screens in real-time, allowing for predictive maintenance and optimal operational conditions.

Furthermore, with the growing emphasis on environmental sustainability, many companies are focusing on developing screens that minimize waste and enhance the recycling of drilling fluids. Innovations that allow for more efficient separation processes can lead to significant cost savings and reduced environmental impact.

Conclusion

The role of shale shaker screens in the oil and gas industry cannot be overstated. As the demand for energy continues to rise, the need for effective and efficient drilling operations is critical. Shale shaker screen manufacturers are at the forefront of this demand, driving innovations that enhance the drilling process. A robust shale shaker equipped with high-quality screens not only optimizes drilling performance but also contributes to overall cost efficiency and environmental stewardship. As the industry evolves, the collaboration between technology and manufacturing will play a vital role in shaping the future of shale shakers and their screens.

-

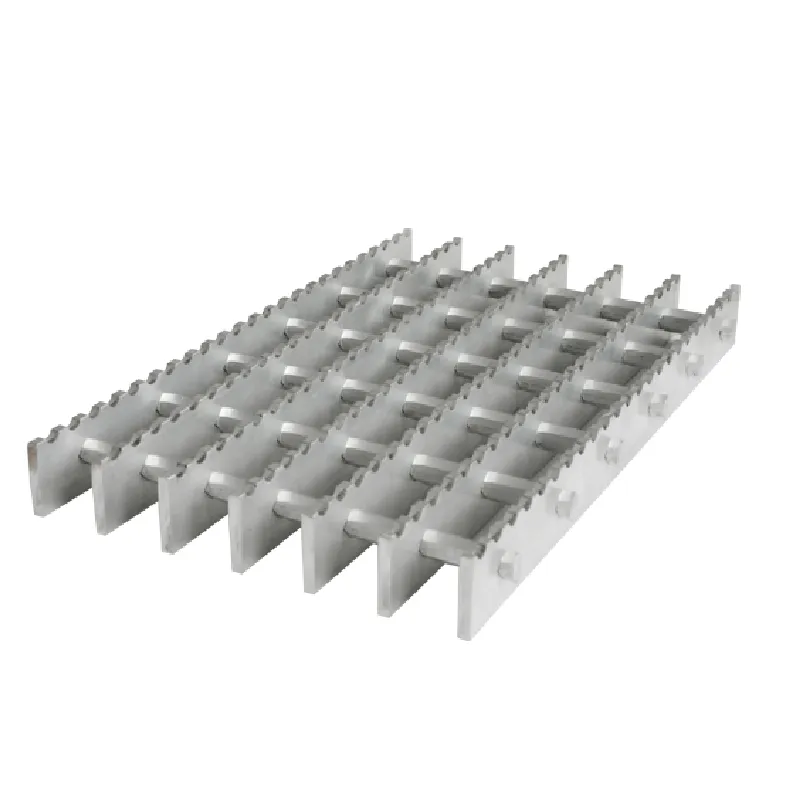

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025