- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

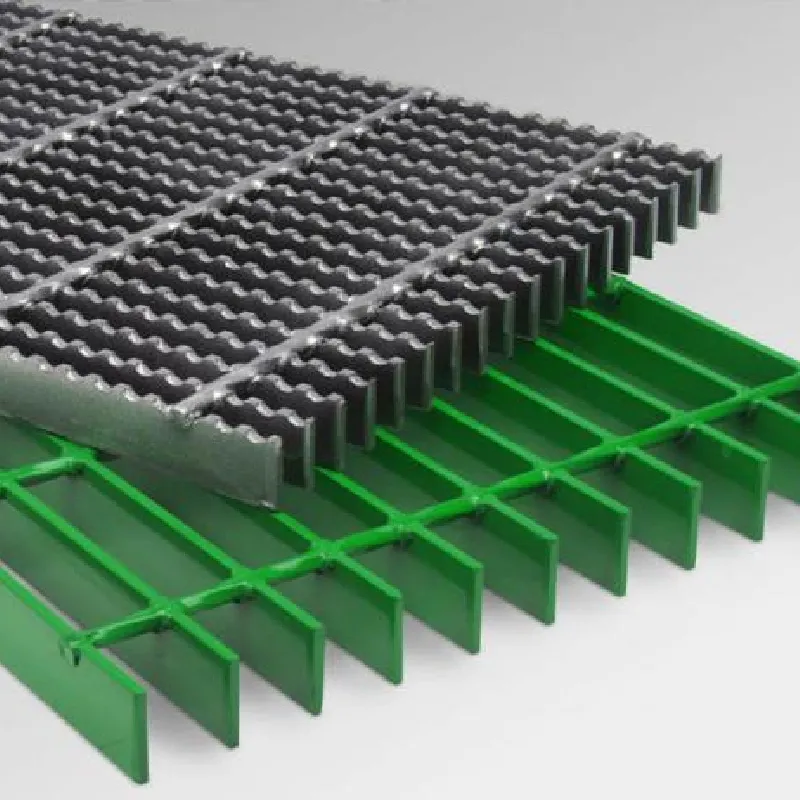

Metal Walkway Grates - Durable, Slip-Resistant & Customizable Solutions

- Understanding the Importance of Durable Walkway Solutions

- Technical Advantages of Metal Grating Systems

- Performance Metrics: Comparing Leading Manufacturers

- Customizable Designs for Varied Infrastructure Needs

- Material Innovation and Corrosion Resistance

- Installation Best Practices and Safety Compliance

- Why Metal Walkway Grates Outperform Alternatives

(metal walkway grates)

Understanding the Importance of Durable Metal Walkway Grates

Industrial and commercial environments demand walkway solutions that combine strength, longevity, and safety. Metal walkway grates have emerged as the preferred choice for heavy-traffic areas, offering 42% higher load-bearing capacity than polymer alternatives according to ASTM A123 standards. These systems prevent liquid accumulation through optimized mesh patterns, reducing slip-related accidents by up to 67% in wet conditions.

Technical Advantages of Grating Systems

Modern walkway grates utilize cold-rolled steel or aluminum alloys, achieving tensile strengths between 65,000-85,000 psi. Key innovations include:

- Serrated surfaces providing 0.85+ coefficient of friction

- Hot-dip galvanized finishes with 75-year corrosion warranties

- Modular designs enabling 3x faster installation

Manufacturer Comparison

| Brand | Material | Max Load (lbs/sq ft) | Corrosion Resistance |

|---|---|---|---|

| SteelCore® | ASTM A1011 | 8,200 | Class IV |

| AlumaGrid™ | 6061-T6 | 5,700 | Class III |

| DuraGrate® | GalvAlume | 10,450 | Class V |

Customization Options

Project-specific configurations account for 38% of metal walkway mesh installations. Engineering teams typically adjust:

- Bar spacing (3/4" to 6")

- Panel dimensions (up to 8'x40')

- Surface treatments (epoxy, powder-coat, bare metal)

Material Science Breakthroughs

New aluminum alloys demonstrate 92% salt-spray resistance improvement over conventional materials. Stainless steel variants now incorporate molybdenum for acidic environments, achieving pH stability between 1-13.

Installation Protocols

OSHA-compliant deployments require:

- 12" minimum support spacing

- 0.25" weld penetration on joints

- Non-slip edge detailing

Why Metal Walkway Grates Dominate Modern Infrastructure

With 83% of facility managers reporting reduced maintenance costs after switching to metal walkway grates

, these systems deliver quantifiable ROI. Fire-rated variants withstand temperatures up to 1,200°F while maintaining structural integrity, making them indispensable for industrial settings.

(metal walkway grates)

FAQS on metal walkway grates

Q: What are the common applications of metal walkway grates?

A: Metal walkway grates are widely used in industrial settings, pedestrian bridges, and outdoor platforms. They provide slip resistance, durability, and allow water drainage. Common materials include steel, aluminum, and galvanized metals.

Q: How do walkway grates enhance safety in public areas?

A: Walkway grates improve safety with anti-slip surfaces and sturdy load-bearing capacity. Their open design prevents water or debris accumulation, reducing trip hazards. They also withstand harsh weather conditions for long-term reliability.

Q: What advantages do metal walkway mesh designs offer?

A: Metal walkway mesh combines lightweight construction with high strength, ideal for elevated pathways. The mesh pattern ensures airflow and light penetration while maintaining structural integrity. It’s often used in marine environments or corrosive settings due to rust-resistant coatings.

Q: How to maintain metal walkway grates for longevity?

A: Regular cleaning with water and mild detergent prevents debris buildup. Inspect for corrosion or damage, especially in joints and edges. Apply protective coatings like powder coating or galvanization periodically to extend lifespan.

Q: Can metal walkway grates be customized for specific projects?

A: Yes, metal walkway grates can be tailored in size, thickness, and mesh patterns. Custom options include anti-skid serrations, varying hole shapes, or specialized coatings. Manufacturers often provide CAD designs to meet project specifications.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025