- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Press-Locked Steel Grating - Hefei PetroMesh | Durable Industrial Solutions

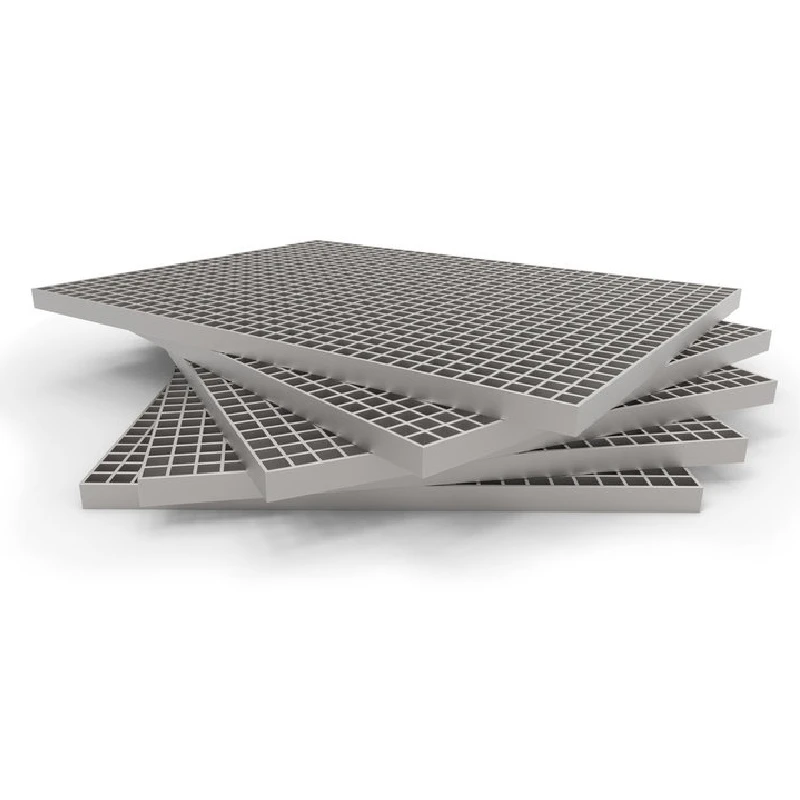

Press-Locked Steel Grating: Durable and Reliable Solution for Industrial Applications

Steel grating is a critical component in industrial infrastructure, offering strength, durability, and versatility for a wide range of applications. Among the various types of steel grating available, Press-Locked Steel Grating stands out as a premium solution designed to meet the demanding requirements of modern industrial environments. Hefei PetroMesh Industrial Co., Ltd., a leading manufacturer in the steel grating industry, offers high-quality Press-Locked Steel Grating that combines advanced engineering with robust performance. This article explores the features, benefits, and applications of Press-Locked Steel Grating, highlighting why it is the preferred choice for industrial projects worldwide.

What is Press-Locked Steel Grating?

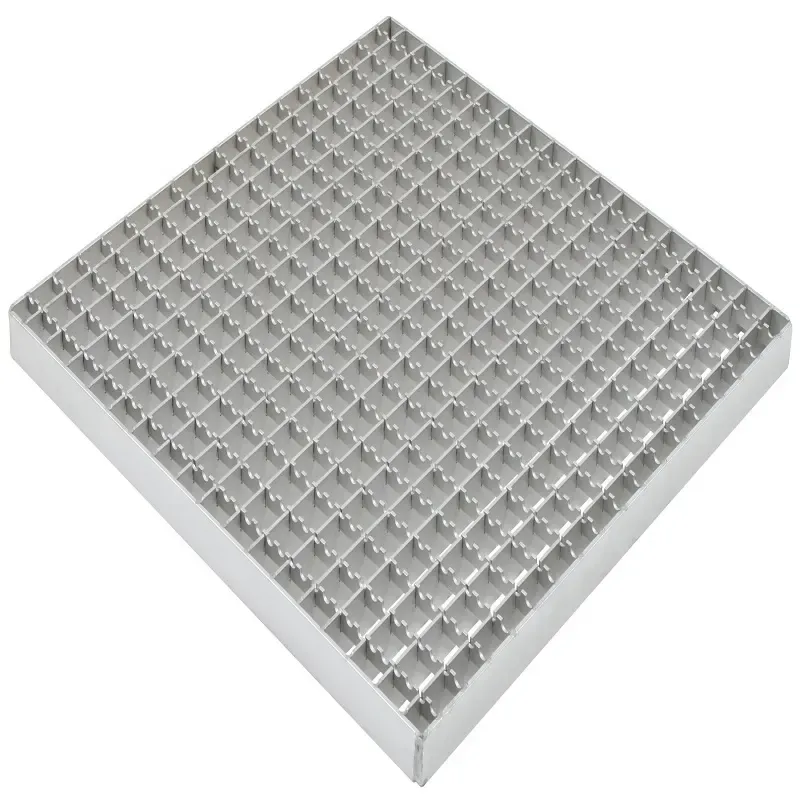

Press-Locked Steel Grating is a type of metal grating manufactured using a specialized pressing process that securely locks the crossbars into the bearing bars. This method ensures a strong, vibration-resistant structure that can withstand heavy loads and harsh environmental conditions. Unlike traditional welded steel grating, which may be prone to corrosion or structural weakness over time, Press-Locked Steel Grating is designed for long-term durability and minimal maintenance.

The manufacturing process involves precision engineering to create a seamless connection between the bearing bars and crossbars. This results in a grating system that is not only strong but also lightweight, making it ideal for applications where weight and strength are critical factors.

Key Features and Technical Specifications

Press-Locked Steel Grating is engineered to meet the highest standards of quality and performance. Below are some of its key features and technical specifications:

- Material: High-strength carbon steel or stainless steel, depending on the application requirements.

- Surface Treatment: Hot-dip galvanizing, powder coating, or other protective finishes to enhance corrosion resistance.

- Load Capacity: Designed to support heavy industrial loads, with standard load ratings ranging from 500 kg/m² to 2000 kg/m².

- Dimensions: Available in various widths (300mm, 400mm, 500mm) and lengths (up to 6 meters), with customizable options.

- Open Area: Optimized for drainage and ventilation, with open areas ranging from 30% to 50%.

- Installation: Easy to install using clips, bolts, or welding, depending on the project requirements.

Applications of Press-Locked Steel Grating

Due to its exceptional strength and versatility, Press-Locked Steel Grating is widely used in various industrial and commercial applications. Some of the most common uses include:

1. Industrial Platforms and Walkways

Press-Locked Steel Grating is ideal for constructing platforms and walkways in factories, warehouses, and processing plants. Its non-slip surface and high load capacity make it a safe and reliable choice for pedestrian and vehicle traffic.

2. Stair Treads and Landings

The grating's slip-resistant design ensures safe access in areas with high foot traffic, such as stairs, landings, and ramps. Its lightweight nature also reduces the structural load on buildings.

3. Drainage and Ventilation Systems

The open structure of Press-Locked Steel Grating allows for efficient drainage and airflow, making it suitable for use in stormwater management, ventilation systems, and underfloor drainage.

4. Equipment Guarding and Enclosures

It is commonly used to create protective barriers around machinery, equipment, and hazardous areas. The grating's robust construction provides both safety and visibility.

Why Choose Press-Locked Steel Grating?

There are several compelling reasons to choose Press-Locked Steel Grating over other types of grating:

1. Superior Strength and Durability

The pressing process ensures a secure connection between the bearing bars and crossbars, creating a grating system that is highly resistant to deformation and wear. This makes it suitable for heavy-duty applications in challenging environments.

2. Corrosion Resistance

With options for hot-dip galvanizing or powder coating, Press-Locked Steel Grating is designed to withstand exposure to moisture, chemicals, and other corrosive elements. This extends the lifespan of the product and reduces maintenance costs.

3. Cost-Effective Solution

Compared to traditional welded grating, Press-Locked Steel Grating requires less material and labor during installation, resulting in lower overall costs. Its long service life also reduces the need for frequent replacements.

4. Customization Options

Manufacturers like Hefei PetroMesh Industrial Co., Ltd. offer customized solutions to meet specific project requirements. This includes adjustments to size, load capacity, and surface finish.

About Hefei PetroMesh Industrial Co., Ltd.

Hefei PetroMesh Industrial Co., Ltd. is a leading manufacturer and supplier of steel grating products, with over a decade of experience in the industry. The company specializes in producing high-quality steel grating solutions for industrial, commercial, and infrastructure projects. Hefei PetroMesh is committed to delivering innovative products that meet international standards and exceed customer expectations.

With a strong focus on research and development, Hefei PetroMesh continuously improves its manufacturing processes to ensure the highest levels of quality and performance. The company's products are widely used in various industries, including oil and gas, chemical processing, power generation, and construction.

Customer Testimonials

Customers who have used Press-Locked Steel Grating from Hefei PetroMesh Industrial Co., Ltd. have consistently praised its performance and reliability:

- "We've been using Press-Locked Steel Grating for our factory walkways, and it has significantly improved safety and durability. The installation was straightforward, and the product has exceeded our expectations." – John D., Industrial Manager

- "The corrosion resistance of the grating has made it ideal for our chemical processing plant. We've experienced no issues even after years of use." – Sarah L., Plant Supervisor

How to Order Press-Locked Steel Grating

For businesses looking to purchase Press-Locked Steel Grating, Hefei PetroMesh Industrial Co., Ltd. offers a seamless ordering process. Customers can contact the company directly via phone, email, or through the official website to discuss their requirements. The company provides detailed specifications, samples, and quotations to ensure that customers receive the right product for their project.

Custom orders are also available, allowing businesses to tailor the grating to their specific needs. Whether it's for a small-scale project or a large industrial facility, Hefei PetroMesh is equipped to deliver high-quality products on time and within budget.

Conclusion

Press-Locked Steel Grating is a reliable and cost-effective solution for industrial applications, offering superior strength, durability, and versatility. With its advanced manufacturing process and customizable options, it is the ideal choice for businesses seeking a long-term grating solution. Hefei PetroMesh Industrial Co., Ltd. continues to lead the industry with its commitment to quality, innovation, and customer satisfaction.

Frequently Asked Questions (FAQ)

1. What materials are used in Press-Locked Steel Grating?

Press-Locked Steel Grating is typically made from high-strength carbon steel or stainless steel, depending on the application requirements. Additional surface treatments such as hot-dip galvanizing or powder coating are available to enhance corrosion resistance.

2. What is the load capacity of Press-Locked Steel Grating?

The load capacity varies depending on the design and material used. Standard load ratings range from 500 kg/m² to 2000 kg/m², with customization options available for heavier applications.

3. Can Press-Locked Steel Grating be customized?

Yes, manufacturers like Hefei PetroMesh Industrial Co., Ltd. offer customization options to meet specific project requirements, including adjustments to size, load capacity, and surface finish.

4. How is Press-Locked Steel Grating installed?

The grating can be installed using clips, bolts, or welding, depending on the project's needs. Its lightweight design and modular structure make installation quick and efficient.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025