- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

3D Shaker Screen-Hefei PetroMesh Co., Ltd.|Industrial Separation & Cost Reduction

3D Shaker Screen: Revolutionizing Industrial Separation with Advanced Technology

Industrial separation processes are critical for ensuring the quality and efficiency of production in various sectors, including oil and gas, mining, and chemical manufacturing. At Hefei PetroMesh Co., Ltd., we have developed the 3D Shaker Screen, a cutting-edge solution designed to optimize separation performance while reducing operational costs. This article explores the innovative features, applications, and benefits of the 3D Shaker Screen, highlighting how it addresses industry challenges and delivers exceptional value to our clients.

Product Overview and Core Functionality

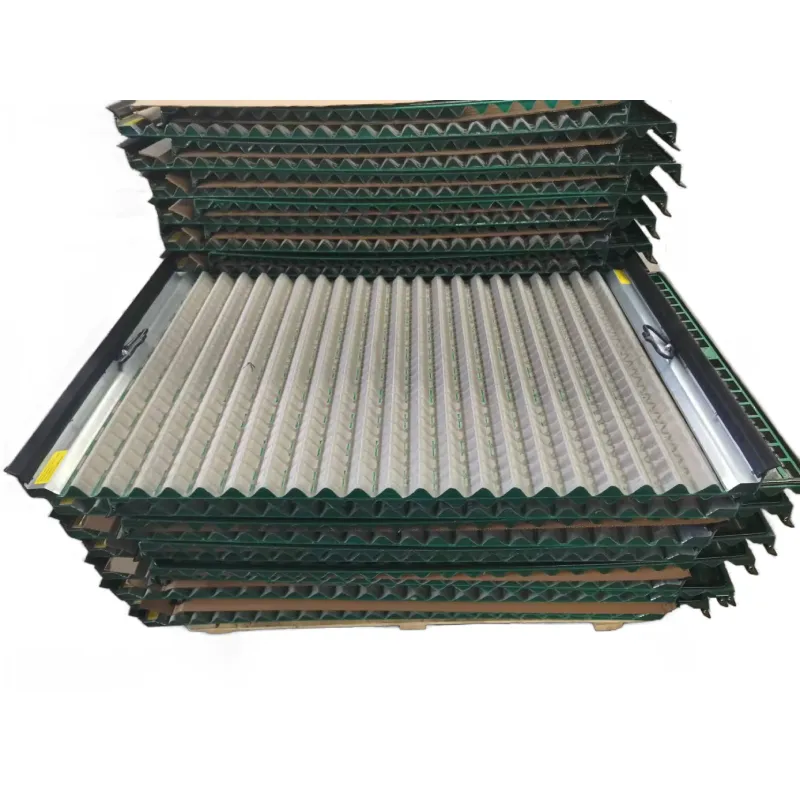

The 3D Shaker Screen is a state-of-the-art screening equipment engineered to enhance the efficiency of solid-liquid and solid-solid separation processes. Unlike traditional flat screens, the 3D Shaker Screen employs a three-dimensional structure that maximizes surface area and improves material flow dynamics. This design allows for more effective particle separation, even in challenging conditions such as high viscosity or fine particle sizes.

Manufactured using advanced materials and precision engineering, the 3D Shaker Screen is built to withstand harsh industrial environments. Its modular design enables easy maintenance and replacement, minimizing downtime and ensuring consistent performance. Whether used in drilling mud purification, mineral processing, or chemical filtration, this product is tailored to meet the diverse needs of modern industries.

Market Demand and Industry Challenges

Traditional separation technologies often face limitations in efficiency, durability, and adaptability. For instance, conventional screens may struggle with clogging, uneven material distribution, or insufficient throughput, leading to increased operational costs and reduced productivity. These challenges are particularly pronounced in industries dealing with viscous fluids or fine particulates, where conventional solutions fall short.

The 3D Shaker Screen addresses these issues through its innovative design. By incorporating a dynamic 3D structure, the screen enhances vibration efficiency, ensuring uniform material distribution and preventing blockages. Additionally, its advanced material composition resists wear and tear, extending the lifespan of the equipment and reducing the need for frequent replacements.

Technological Innovation and R&D Capabilities

As a leader in industrial filtration solutions, Hefei PetroMesh Co., Ltd. invests heavily in research and development to stay at the forefront of technological advancements. Our team of engineers and material scientists has developed the 3D Shaker Screen using proprietary technologies that combine structural optimization with high-performance materials. This includes:

- Dynamic Vibration System: A patented vibration mechanism that adjusts to varying material loads, ensuring optimal screening efficiency.

- High-Strength Alloy Construction: Utilizing corrosion-resistant alloys to maintain structural integrity in aggressive environments.

- Modular Design: Allows for easy customization and scalability to suit different industrial applications.

These innovations not only improve the performance of the 3D Shaker Screen but also align with global trends toward sustainable and energy-efficient industrial practices.

Proven Performance and Customer Testimonials

The effectiveness of the 3D Shaker Screen is backed by extensive field testing and real-world applications. For example, a major oil and gas company reported a 30% increase in drilling mud filtration efficiency after implementing the 3D Shaker Screen, significantly reducing downtime and maintenance costs. Another client in the mining sector noted a 25% improvement in mineral recovery rates, directly contributing to higher profitability.

Customer feedback highlights the product's reliability and ease of integration into existing systems. One user stated, "The 3D Shaker Screen has transformed our separation process. It’s not only more efficient but also requires minimal maintenance, which is a game-changer for our operations." Such testimonials underscore the product's value in addressing industry-specific challenges.

Applications and Customization Options

The 3D Shaker Screen is versatile, with applications across multiple industries:

- Oil and Gas: Used for drilling mud purification and solid-liquid separation in offshore and onshore operations.

- Mineral Processing: Enhances the efficiency of ore screening and fine particle recovery.

- Chemical Manufacturing: Ensures precise filtration of viscous chemicals and slurries.

To meet the unique requirements of each client, Hefei PetroMesh offers customized solutions. Our engineers work closely with customers to design screens tailored to specific material properties, throughput demands, and operational conditions. This level of customization ensures that the 3D Shaker Screen delivers optimal performance in every application.

Environmental and Safety Compliance

Sustainability and safety are core priorities in the development of the 3D Shaker Screen. The product is designed to minimize energy consumption while maximizing efficiency, aligning with global efforts to reduce carbon footprints. Additionally, all materials used comply with international environmental standards, ensuring minimal impact on ecosystems.

From a safety perspective, the 3D Shaker Screen undergoes rigorous testing to meet industry safety regulations. Its robust construction and user-friendly design reduce the risk of accidents, making it a reliable choice for industrial environments.

Logistics and Packaging Solutions

For bulk orders, Hefei PetroMesh provides durable, industry-standard packaging to ensure the safe transportation of the 3D Shaker Screen. Our logistics partners handle shipments globally, with tracking systems to monitor delivery progress. Customers can also opt for on-site installation support, ensuring seamless integration into their facilities.

Comprehensive Customer Support

We are committed to providing exceptional after-sales service to our clients. Our dedicated support team offers:

- Technical Consultation: Expert guidance on installation, operation, and troubleshooting.

- Training Programs: Customized training sessions to ensure operators are fully proficient with the equipment.

- Warranty and Maintenance: Comprehensive warranty coverage and scheduled maintenance plans to maximize equipment lifespan.

Whether you need immediate assistance or long-term support, our team is here to ensure your success with the 3D Shaker Screen.

Conclusion and Next Steps

The 3D Shaker Screen from Hefei PetroMesh Co., Ltd. represents a significant advancement in industrial separation technology. By combining innovative design, advanced materials, and customer-centric solutions, this product delivers unparalleled efficiency, reliability, and cost savings. For more information or to request a consultation, visit our product page or contact our team directly.

Frequently Asked Questions (FAQ)

Q1: What materials are used in the construction of the 3D Shaker Screen?

A: The screen is made from high-strength, corrosion-resistant alloys designed to withstand harsh industrial conditions. These materials ensure durability and long-term performance.

Q2: Can the 3D Shaker Screen be customized for specific applications?

A: Yes, we offer tailored solutions to meet the unique requirements of different industries. Our engineers work closely with clients to design screens optimized for their specific needs.

Q3: What is the expected lifespan of the 3D Shaker Screen?

A: With proper maintenance, the screen can last for several years, depending on usage conditions. Our designs prioritize longevity to minimize replacement costs.

Q4: How does the 3D Shaker Screen improve separation efficiency?

A: The 3D structure enhances vibration efficiency and material flow, reducing clogging and ensuring uniform screening. This leads to higher throughput and better separation results.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025